GENMAX Ultrasonic Quilting Machine Impresses Mexican Visitor

A Mexican textile business owner visited our facility. They came to see the GENMAX ultrasonic quilting machine in action. This demo showed our ties with different customers in Mexico. We connect with both established manufacturers and newer workshop owners. As ultrasonic quilting technology grows in South America, hands-on evaluations are key. They help business owners make important equipment choices.

Seeing is Believing: Hands-On with Ultrasonic Technology

Our visitor came with clear questions. He wanted to know how ultrasonic quilting could improve his production line. Instead of a lengthy presentation, we went straight to the machine for a practical demo.

“I need to understand how this works before deciding,” he said, examining the machine. “In my shop, every investment must pay off quickly.”

We demonstrated the basic operation, showing how ultrasonic technology creates patterns without the need for traditional needle and thread. He was initially skeptical but changed his mind after seeing the results.

“I’ve heard about ultrasonic quilting from others in Mexico, but seeing it in person is a game changer,” he noted while watching the machine produce a sample. “The process is much cleaner than I expected.”

This reaction happens often with visitors from Mexico and South America. There, traditional quilting methods have always been common. We focus on practical demonstrations of ultrasonic technology, as this shift is important.

Sales and technical team en route to meet with a Mexican textile industry client interested in ultrasonic quilting technology for their manufacturing operations.

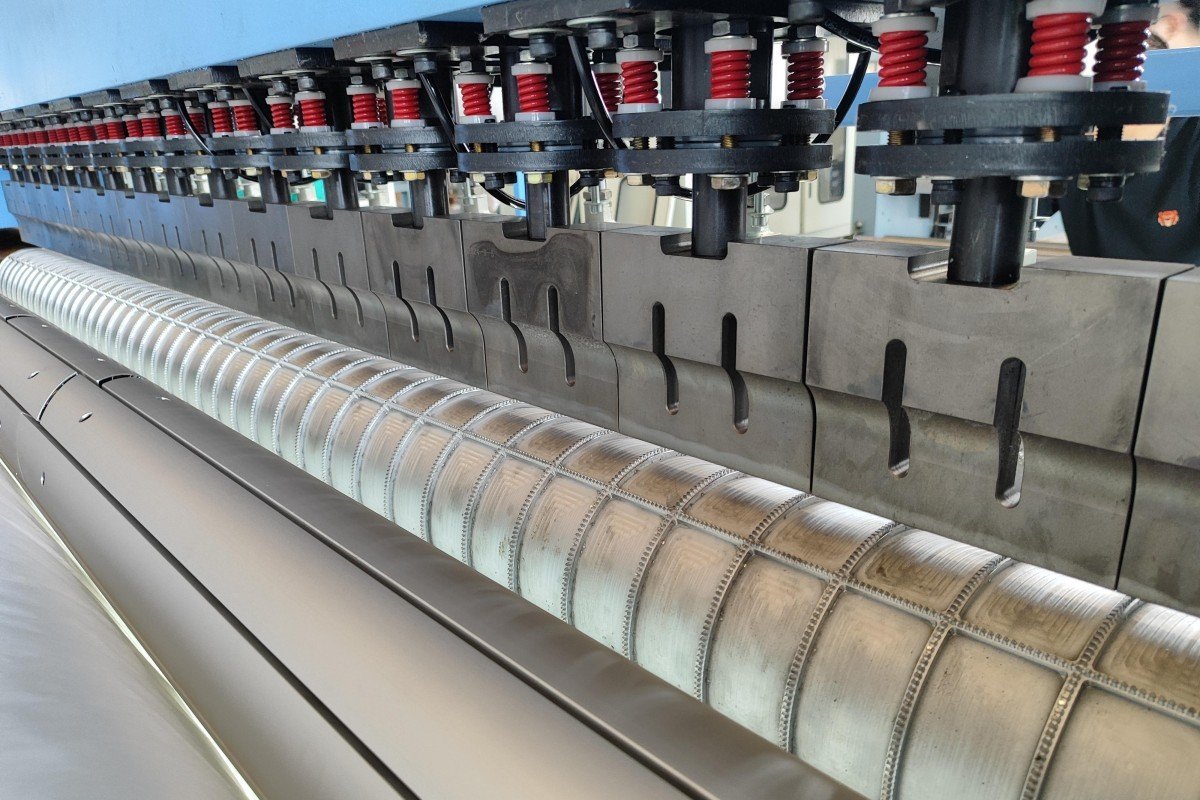

Focus on the Flower Roller System

The visitor focused on the flower roller system, examining how it creates patterns. He wanted to know about roller durability, pattern options, and the speed of pattern changes during production.

“These patterns look great,” he remarked, handling a fresh sample from the machine. “My customers would love this level of detail.”

We showed him how to change the rollers. We emphasized that his team could make quick adjustments. They could do this even with limited technical staff and without complicated procedures. This feature is especially important for medium-sized operations in Mexico, where production flexibility is key but technical resources may be limited.

“In Mexico, we need to change designs often to meet market demands,” he explained. “If changing patterns is hard, it creates bottlenecks.”

He spent a lot of time looking at different flower rollers. He asked about custom options and compared the embossing depth on various fabrics. We provided examples of popular patterns used by other Mexican customers, which helped him visualize how the technology could fit his product lines.

Mexican textile manufacturer carefully inspecting the mechanical components and ultrasonic bonding system of the needle-free quilting machine during a detailed technical assessment.

Practical Questions for Real-World Use

During the visit, we talked about daily operational issues in textile manufacturing in Mexico:

- Machine maintenance needs and service intervals

- Power consumption compared to traditional methods

- Training time for operators with basic technical skills

- Parts availability and service response times in Mexico

- Compatibility with locally available fabrics

- Production speeds under normal operating conditions

- Noise levels and floor space requirements

We answered every question clearly. We shared our experiences from similar-sized operations in Mexico. There, GENMAX machines have worked well. Our extensive customer base in Mexico allows us to provide specific information rather than generic answers.

“Your other customers in Puebla and Guadalajara face the same challenges we do,” he observed. “It’s helpful to know how they’ve implemented this technology.”

The visitor was very curious about how the machine works in Mexico’s hot summers. Keeping the temperature right can be hard in some places. We explained the cooling system and shared strategies used by our Mexican customers in similar environments.

Evaluating the Finished Product

The most convincing part of the demonstration was when he examined finished products from the ultrasonic quilting machine. Our visitor inspected several samples, checking quality and asking about production speeds.

He asked for a test with material like his current work. This would let him compare ultrasonic results to his existing products. The improvement in pattern definition was clear.

“The clarity of these patterns would definitely stand out in our market,” he said while examining the sample. “And the production speed is much faster than our current method.”

We gave him several finished samples to take back to Mexico. This lets his team check the quality and talk about possible investments. This hands-on method works well for our South American customers. They prefer real results to technical details.

Before he left, we took a photo with the ultrasonic quilting machine. It’s a simple memento of our hopes for a successful business relationship. This photo is part of our gallery. It shows visitors from Mexico and South America who came to experience GENMAX technology firsthand.

South American Success Stories Influence Decisions

During the visit, we shared examples of how other businesses in South America have successfully integrated GENMAX ultrasonic quilting machines. These regional success stories resonated with our Mexican visitor.

“We’ve been watching trends in Colombia and Brazil, where ultrasonic quilting has really taken off,” he mentioned. “It seems like the technology is proving itself across South America.”

Indeed, GENMAX has seen remarkable growth in South America, with our machines now operating in Argentina, Brazil, Chile, Colombia, Ecuador, Peru, and Mexico. This regional adoption creates a strong reference network for new customers.

Our service network has expanded with our sales. We now offer dedicated technical support across Mexico and South America. This infrastructure gives customers confidence that their investment will be supported long-term.

The Mexican Market Context

Mexico is a key market for GENMAX, with its strong textile manufacturing tradition and rising demand for advanced technologies. Our visitor’s questions reflected the specific concerns of Mexican manufacturers today.

“In Mexico, we’re not just competing with each other but with imports from Asia,” he explained. “Technology that improves quality while controlling costs is essential.”

Many manufacturers in Mexico are now interested in ultrasonic quilting technology. They want to improve quality and design but also keep prices low. GENMAX’s machines offer this balance, which explains their growing popularity in the region.

The visitor talked about how government programs are helping Mexican manufacturing. These initiatives have created new chances for technology investments. Some of these programs also support updating equipment. We shared how other Mexican customers have navigated these programs when purchasing GENMAX equipment.

Growing with Mexican Textile Producers

GENMAX keeps growing its connections with textile businesses in Mexico. This includes everything from small workshops to larger companies. Our ultrasonic quilting technology helps companies improve quality and efficiency. It does this without adding extra complexity.

With reliable support throughout Mexico and straightforward training programs, GENMAX provides accessible solutions that help textile producers of all sizes improve their capabilities and grow their businesses.

Our Mexican visitor left with samples and photos. He shared his thoughts: “What I appreciate most is seeing a machine that’s already proven itself in our region.” “I’m not risking unproven tech. I’m looking at a system that works for businesses like mine in Mexico and South America.””

GENMAX has thrived in the region. We provide advanced technology that gives a competitive edge. It’s also practical for real-world manufacturing in Mexico and South America.

We can’t wait to follow up with our visitor. We hope to add another successful GENMAX installation to Mexico’s vibrant ultrasonic quilting community.