Bonnell Spring Coiling Machine

YHJ High Speed Bonnell Spring Coiling Machine manufactures mattress springs through automated production. Completes wire coiling, end knotting, heat treatment, and delivery in one continuous cycle. Produces 90-95 springs per minute using servo motor drive with PLC control system coordination.

Download PDF

Customer Service

Share your contact information – our engineers respond 24/7.

Capacity: 90-95pcs/min

Customer Service

Share your contact information – our engineers respond 24/7.

Guatemalan Customer Feedback

Customer Service

Share your contact information – our engineers respond 24/7.

Bonnell Spring Coiling Machine Features Overview

High Production

Customer Service

Share your contact information – our engineers respond 24/7.

Complete Process Integration

Customer Service

Share your contact information – our engineers respond 24/7.

PLC Control

Customer Service

Share your contact information – our engineers respond 24/7.

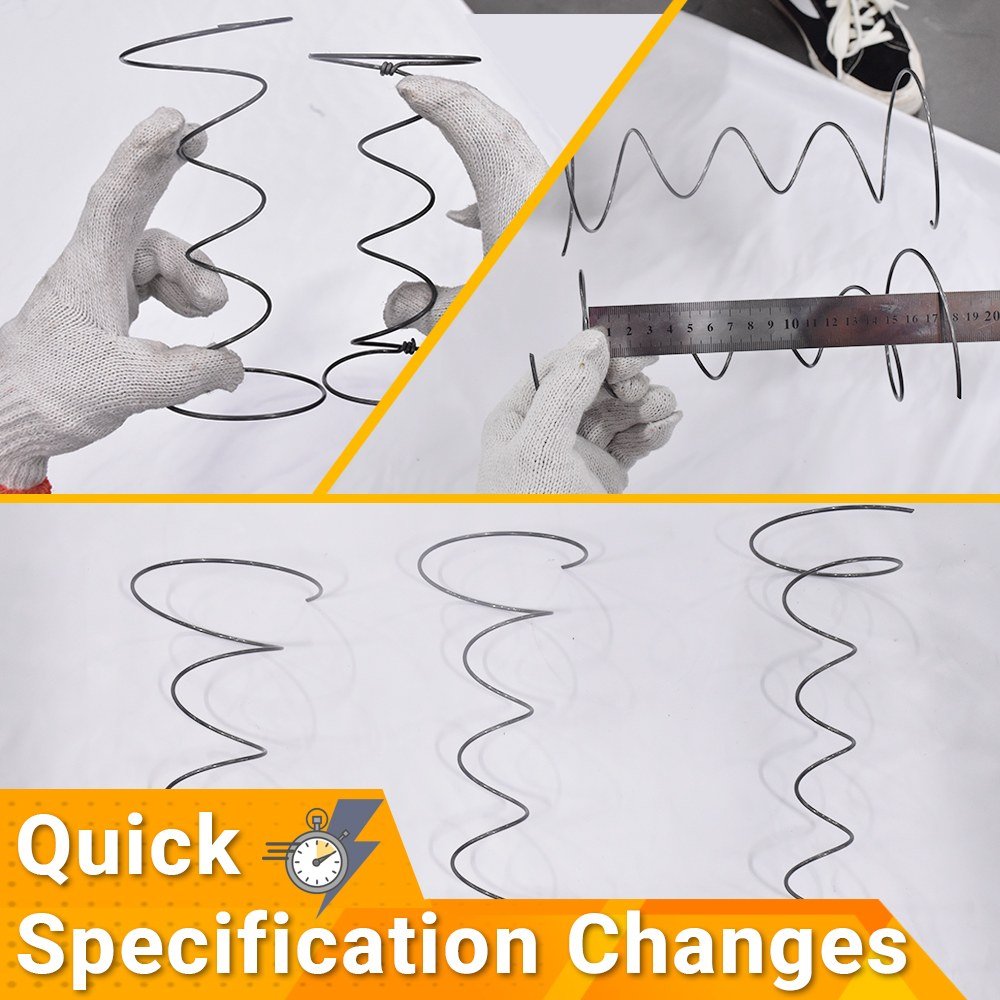

Quick Specification Changes

Customer Service

Share your contact information – our engineers respond 24/7.

Superior Spring Quality

Customer Service

Share your contact information – our engineers respond 24/7.

Bonnell Spring Coiling Machine Technical Specification

|

MODEL |

YHJ100 |

YHJ80E |

|---|---|---|

|

Capacity |

90-95pcs/min |

80pcs/min |

|

Spring End Ring |

Φ62-Φ95mm |

Φ65-Φ95mm |

|

Steel Wire Gauge |

Φ1.9-Φ2.4mm |

Φ1.9-Φ2.4mm |

|

Spring Height |

80-190mm |

80-190mm |

|

Convolutions |

4-7 Turns |

4-7 Turns |

|

Main Drive Power |

600W |

550W |

|

Swift Frame Power |

2.2 KVA |

2.2 KVA |

|

Heat Treatment |

17 KVA |

17 KVA |

|

Weight |

2650KG |

1500KG |

|

Power Requirement |

380V,3 Phase,50-60HZ |

380V,3 Phase,50-60HZ |

What Our Customers Say

Guatemalan Mattress Manufacturer Enhances Spring Production with GENMAX Automation

GENMAX Bonnell Spring Core Line: Softer Mattresses, Higher Output for Türkiye Manufacturers

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Customer Service

Share your contact information – our engineers respond 24/7.

Most Popular Questions

The speed is regulated by a frequency transformer that controls the worm and gear decelerator system.

The machine uses a worm and gear decelerator system for power transmission.

The YHJ features an automatic lubrication system that is computer-controlled, ensuring proper lubrication of the knotting heads.

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.