Bonnell Spring Assembling Machine

Bonnell Spring Assembly Machine (CWJ) automatically connects individual spring units with helical wires forming complete assemblies. 17-20 customizable jaws, 2-meter bed width, single-operator design. Features servo motor technology, automatic wire feeding, precision cutting, continuous ejection.

Download PDF

Customer Service

Share your contact information – our engineers respond 24/7.

Automatic High Speed Bonnell Spring Assembling Machine For Mattress

Customer Service

Share your contact information – our engineers respond 24/7.

Automatic Spring Bed Core Production Line

Customer Service

Share your contact information – our engineers respond 24/7.

Bonnell Spring Assembling Machine

Single-Operator Efficiency

Customer Service

Share your contact information – our engineers respond 24/7.

Advanced Wire Processing

Customer Service

Share your contact information – our engineers respond 24/7.

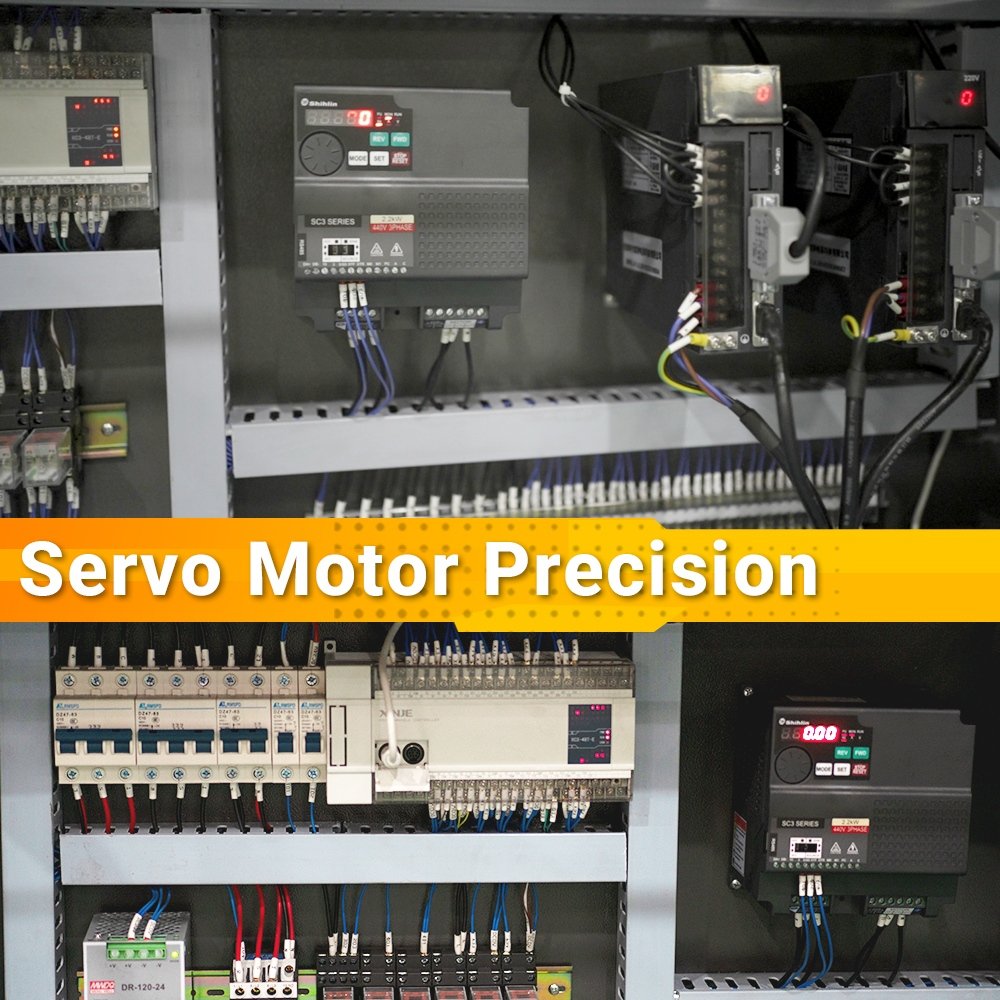

Servo Motor Precision

Customer Service

Share your contact information – our engineers respond 24/7.

Maintenance-Free Operation

Customer Service

Share your contact information – our engineers respond 24/7.

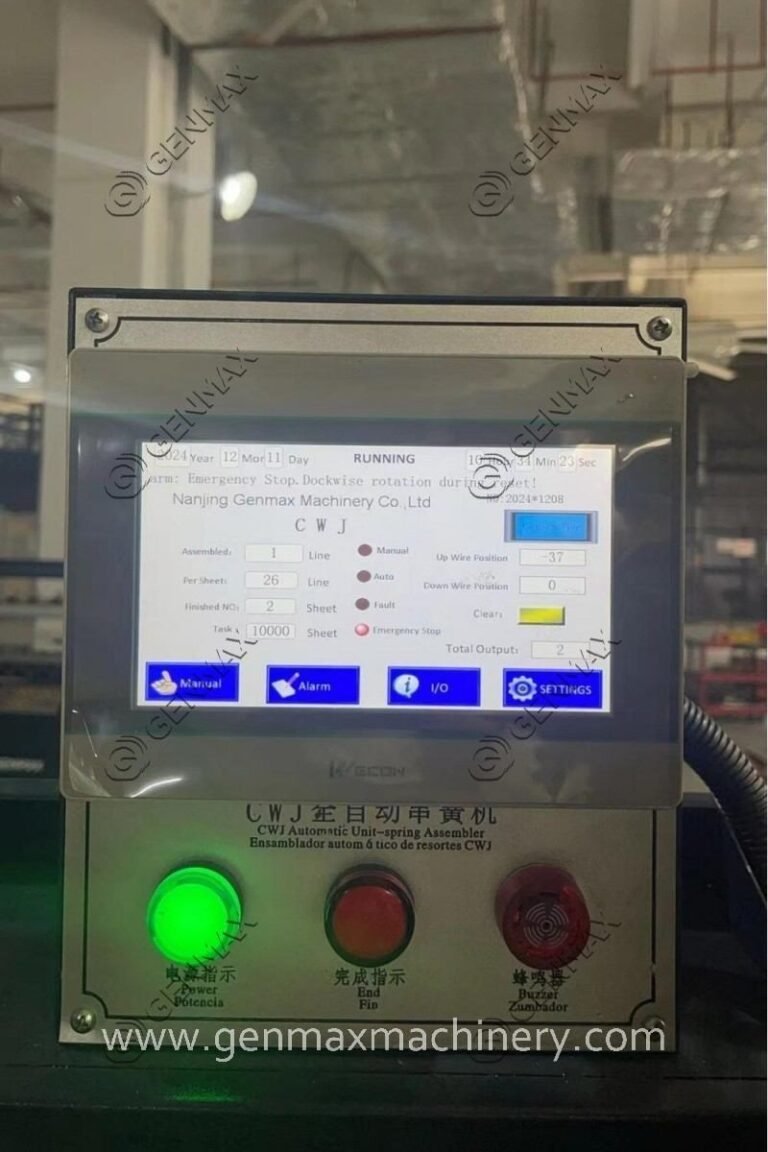

Flexible Production Control

Customer Service

Share your contact information – our engineers respond 24/7.

Bonnell Spring Assembling Machine Technical Specification

|

Spring Type |

Bonnell Spring |

Max Width |

2m |

|

Capacity |

80 Sheets /8 Hours(1800MM*2000MM) |

Diameter of Wire |

2.0mm-2.4mm |

|

Turns of Spring |

4-7 |

Height of Spring |

120-200mm |

|

Height Wire Gauge |

Φ1.3-Φ1.5mm (Option:Φ1.6mm) |

||

|

Spring End Ring |

Φ1.8-Φ2.4mm |

Jaws Spec |

88mm Jaws Φ82-Φ88mm |

|

Power |

4.1KW |

Power Supply |

3-Phase, 380V 50Hz |

|

Dimension |

3000×2200×1800mm |

Weight |

950Kg |

What Our Customers Say

Guatemalan Mattress Manufacturer Enhances Spring Production with GENMAX Automation

GENMAX Bonnell Spring Core Line: Softer Mattresses, Higher Output for Türkiye Manufacturers

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Customer Service

Share your contact information – our engineers respond 24/7.

Most Popular Questions

The speed is regulated by a frequency transformer that controls the worm and gear decelerator system.

The machine uses a worm and gear decelerator system for power transmission.

The YHJ features an automatic lubrication system that is computer-controlled, ensuring proper lubrication of the knotting heads.

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.