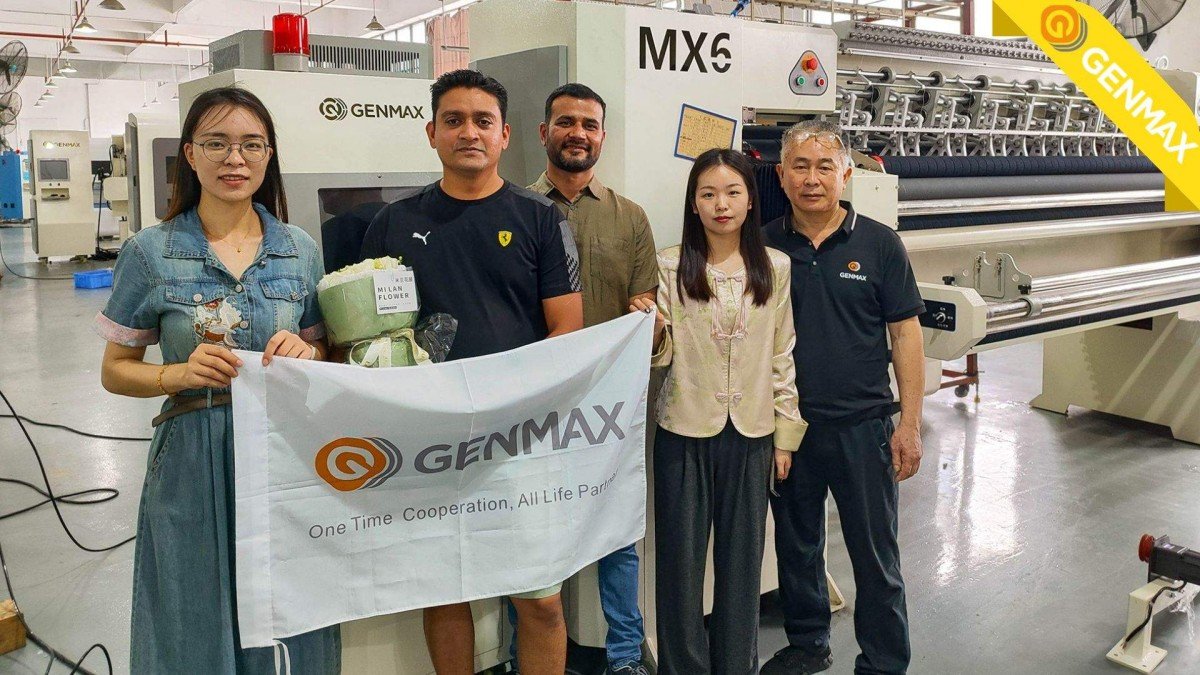

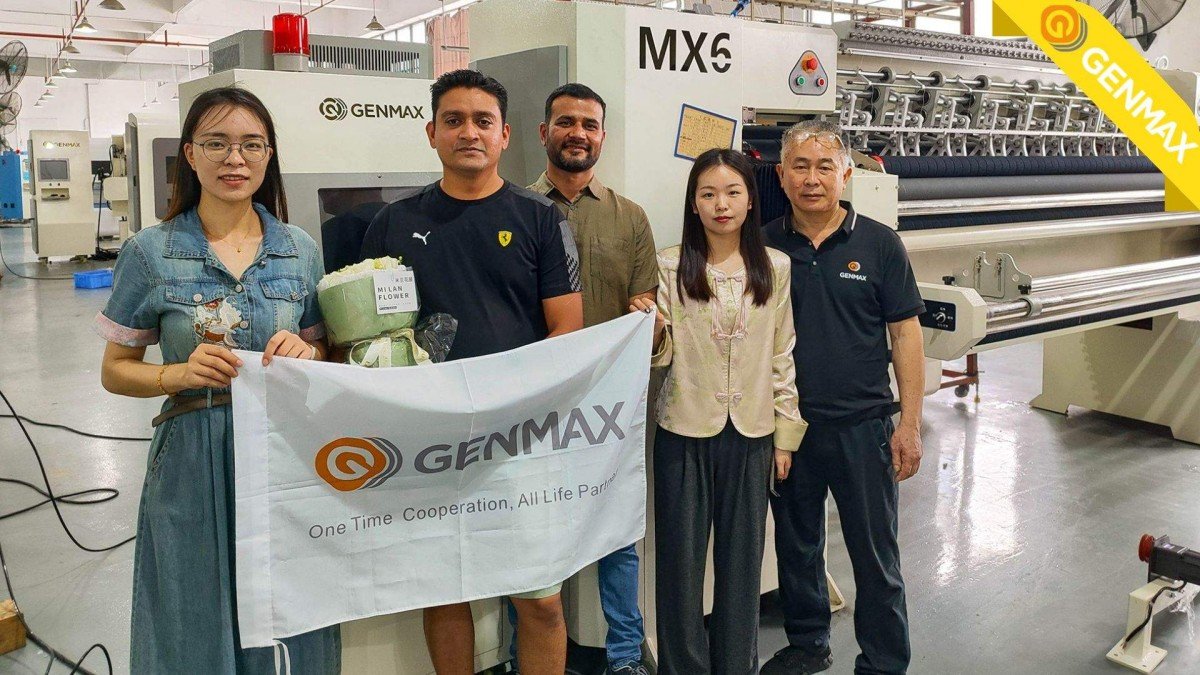

Australian Home Textile Delegation Experiences GENMAX’s Industrial Quilting Excellence

What does it take to keep up in today’s home textile industry? For a group of Australian bedding experts, the answer was simple: leave the boardroom and witness innovation firsthand. What brought them to GENMAX’s factory? It’s where ideas meet machines to tackle real production challenges.

This wasn’t a sightseeing trip. The Australian delegation had a clear goal. They looked for practical solutions. Rising labor costs, changing market demands, and the need for better quality drove this effort. They wanted to explore how industrial quilting technology could improve their bedding. By doing this, they could deliver it with greater speed and efficiency. GENMAX was ready to show—not tell—how that was possible.

Why Australia’s Textile Leaders Came To GENMAX

Australian home textile makers aren’t strangers to change. The industry faces higher labor costs and changing consumer demands. There is also a new focus on quality and sustainability. For many, the solution is smarter manufacturing. This technology provides quality at scale while keeping flexibility.

The delegation included business owners, production managers, and technical experts. Their goal was clear: find solutions that balance efficiency, quality, and adaptability. GENMAX’s reputation for innovation in industrial quilting made it a natural stop.

Curious About How Your Team Can Tackle Similar Challenges?

Get in touch with us for a practical conversation about your production goals.

First Impressions—More Than Just Machines

Welcoming Curiosity

From the start, the GENMAX team set a tone that was open, practical, and honest. No overblown promises—just real talk about what works, what doesn’t, and how to get the most out of every machine on the floor. The Australian visitors didn’t just want to see shiny new equipment. They wanted to understand the “why” behind every feature, and how these choices play out in a real production environment.

Want to see these machines in action for yourself? Book a demo with our team and experience the difference firsthand.

Why the MX6 Caught Their Eye

Australian manufacturers know the pressure to innovate. They’re juggling labor costs, shifting market tastes, and the need for standout products. The MX6 stood out for its practical features:

- Jump, Continuous, and Striped Patterns: Versatility for different mattress topper designs.

- 0.5-Inch Row Pitch: Allows more detailed, custom quilting effects.

- Speeds Up to 1300 RPM: Faster cycles without sacrificing stitch quality.

- Optional Precision Slitting Device: For clean, efficient panel separation.

- Aluminum Swing Arms: Reduces vibration, keeping stitches crisp even at high speeds.

- Advanced Servo Control: Enables true 360° quilting, opening up creative possibilities.

Curious how these features could fit your operation? Explore detailed MX6 specifications or compare with our other quilting machines.

A Closer Look—MX6 in Action

The MX6 isn’t just about power; it’s about control. The Windows-based system gives operators an intuitive interface—no guesswork, just clear commands. Automatic thread break detection keeps downtime to a minimum, and adjustable stitch length (from 3 to 8mm) means you can dial in the exact finish you want.

Visitors watched as the MX6 created strong, three-dimensional quilting effects on mattress toppers. The servo control system and precise row pitch delivered patterns with depth and clarity—something that’s tough to achieve with older machines.

Honest Pros and Cons

Where the MX6 Shines

- Speed and Versatility: Handles a range of patterns and materials—no need for frequent changeovers.

- Operator-Friendly: The Windows system and auto thread break detection mean less training time and fewer errors.

- Consistent Quality: Servo control and reduced vibration keep every stitch on point.

What to Consider

- Initial Setup: Like any advanced machine, the MX6 takes some initial setup. But with clear instructions and GENMAX support, most teams are up and running quickly.

- Pattern Complexity: The MX6 excels at three-dimensional effects and complex patterns—but if you only ever run simple, repetitive designs, you might not use its full potential.

Need help deciding if the MX6 fits your needs? Contact our quilting experts for an honest, jargon-free discussion.

Ready to upgrade your quilting line? Contact GENMAX for a demo, sample, or a straight-talking chat about how the MX6 can fit into your workflow. Or browse our full range of mattress manufacturing solutions for more options.