Boosting Mattress Production in Riyadh with GENMAX’s Precision Machinery and Support

In the mattress and home textiles industry, success comes from merging technology with great service.

A top mattress maker in Riyadh, Saudi Arabia, wanted to improve their mattress topper production. They sought better efficiency, top quality, and steady output.

Partnering with GENMAX, they got advanced quilting and cutting machines. They also adopted a personalized service program to ensure success.

Tackling Production Challenges with Custom Solutions

Making mattress toppers in large quantities takes more than machines. It also needs a good understanding of challenges. Plus, there must be a commitment to work on solutions together.

The Riyadh Client Faced:

- Thread breakages and inconsistent stitch quality

- Limited pattern options and fabric adaptability

- Cutting process inefficiencies affecting output

- A need for skilled operators familiar with advanced machines

- Demand for quick, local technical support to reduce downtime

GENMAX doesn’t just provide equipment. We form a partnership to enhance your whole production process.

Machinery Built for Durability and Precision

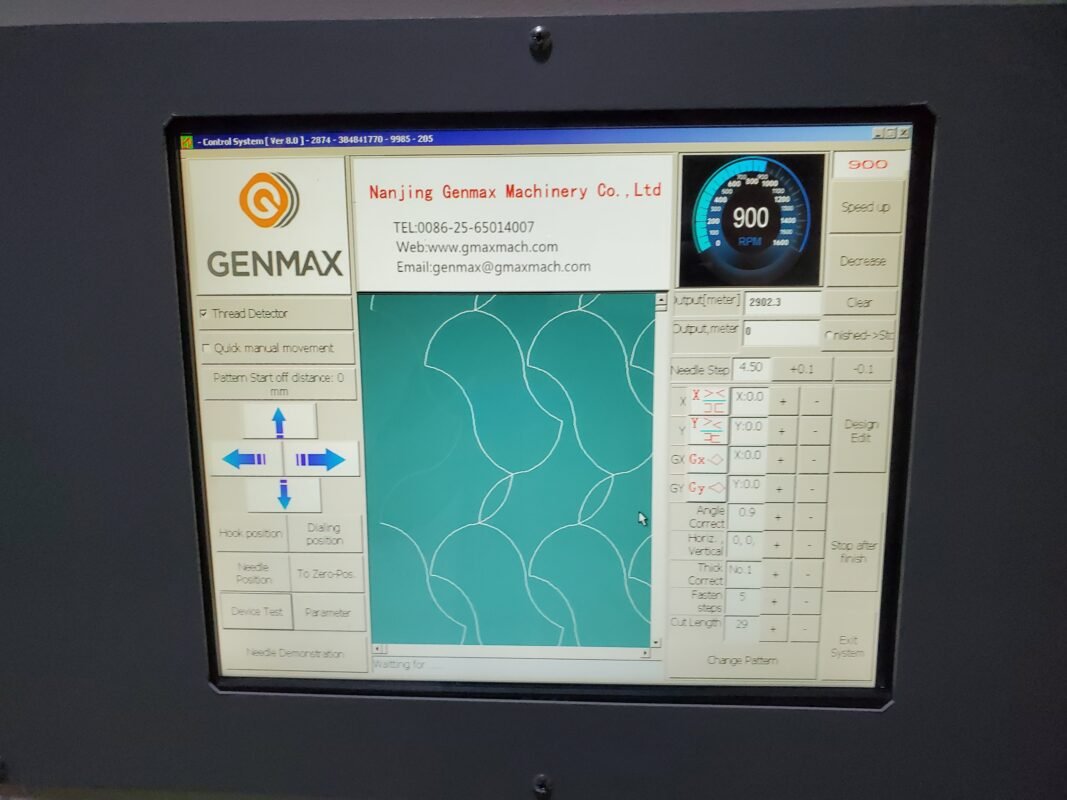

Our MX6 Quilting Machine and CJ4 Cutting Machine highlight GENMAX’s promise of quality and reliability.

- Imported Panasonic Servo Motors for smooth and precise motion

- Premium Sealed Bearings and strong materials for heavy-duty use

- User-friendly Computerized Interfaces to simplify complex programming

- Automatic Fault Detection and Stop Controls to protect materials and cut waste

- Adjustable Presser Foot and Needle Settings for various fabrics used in mattress toppers

These machines are designed for superior performance and easy operation.

The GENMAX Service Promise: Excellence Beyond Machinery

What sets GENMAX apart is our commitment to your operational success:

Careful On-Site Installation and Commissioning

Our engineers calibrate each machine. They also integrate it smoothly into your production line. They base this on your specific materials and processes.

Local Training Empowerment

We provide hands-on training at your site. This helps your operators and maintenance teams learn skills. They can improve machine performance and fix problems quickly.

Proactive After-Sales Support

GENMAX has a strong local presence. This means we can offer quick technical help, preventive maintenance, and spare parts. So, your production runs smoothly.

Collaborative Process Optimization

We partner with your management team to find inefficiencies. Then, we improve workflows. This leads to lasting boosts in productivity and quality.

Delivering Measurable Impact

Since using GENMAX solutions, the Riyadh manufacturer has seen:

- Increased quilting and cutting throughput, meeting growing market needs

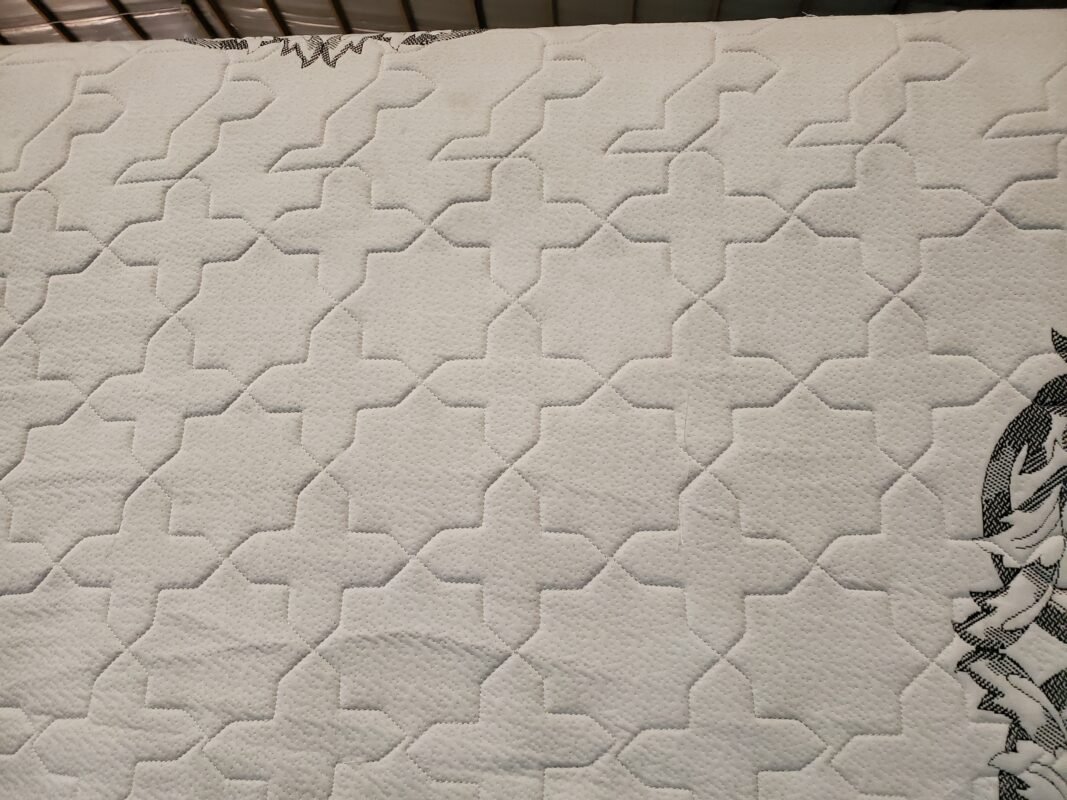

- Better stitch consistency and product quality with fewer defects

- Fewer operator errors through easy-to-use controls and expert training

- Lower maintenance costs and longer machine lifespan due to quality components

- Improved uptime backed by responsive, local technical support

Client Success at a Glance

| Metric | Before GENMAX Partnership | After MX6 & CJ4 Installation | Improvement |

| Quilting speed (RPM) | 800 | 1300 | +62.5% |

| Thread break downtime | Frequent | Minimal | Significant drop |

| Cutting precision | Manual, variable | Automated, consistent | Major improvement |

| Operator skill level | Limited | Comprehensive training | Enhanced proficiency |

| Production uptime | Moderate | High | Increased output |

Why GENMAX?

- High-quality machinery made with durable imported components

- Customized solutions designed for mattress topper manufacturing

- Complete support including installation, training, maintenance, and consulting

- Strong local presence for fast response and minimal downtime

- Partnership focus on understanding and solving your unique production challenges

GENMAX invites you to boost your mattress topper production. We offer precise machinery and outstanding support.

Reach out to learn how our custom solutions can boost your manufacturing operations. We focus on style and efficiency.