GENMAX Quilting Innovation Captivates Peruvian Textile Leader

A leading Peruvian home textile maker came to our demo facility. They wanted to check out GENMAX quilting technology for their expanding production line. This visit highlights our growth in South America, where GENMAX has built a solid presence in textile manufacturing.

Real-World Testing Yields Real Results

The manufacturer came with a challenge. They brought their own materials, like light cotton sheets and heavy comforters. They were eager to see how our equipment would handle their fabrics.

“We need machines that can manage our full product line without constant tweaks,” the manufacturer said. “Previous machines work well with standard materials but struggle with our premium options.”

Instead of a flashy presentation, we ran a simple production test with their materials. The GENMAX quilting machine switched easily between fabric weights and thicknesses, keeping stitch quality consistent.

An unexpected tension issue arose with one tricky fabric. Our technical team quickly fixed the problem, showing how the machine could adapt to this tough material.

“Now I’m seeing something valuable,” the visitor noted. “How your equipment handles challenges, not just ideal situations.”

Addressing South American Production Realities

The conversation shifted to practical implementation. The manufacturer used photos of their Lima facility to highlight common challenges for South American textile producers. These include limited space, an unstable power supply, and complicated workflows.

Their questions reflected concerns familiar to our South American customers:

- How fast is technical support in Peru?

- Are maintenance parts available locally?

- What training is provided for staff with limited tech skills?

We explained our broad South American service network, where we support many installations with local technicians and parts inventory. This infrastructure clearly addressed their worries about ongoing support.

Performance Metrics That Matter

The financial discussion focused on production improvements. The manufacturer shared output figures and requested realistic projections based on the GENMAX quilting machine’s capabilities.

We shared data from GENMAX installations in South America, like Colombia, Brazil, and Chile. Customers in these areas have gained a lot in productivity while keeping quality high.

“These numbers from other South American manufacturers are exactly what I needed to see,” the visitor said. “They face the same market pressures we do.”

Technical Depth Beyond Surface Features

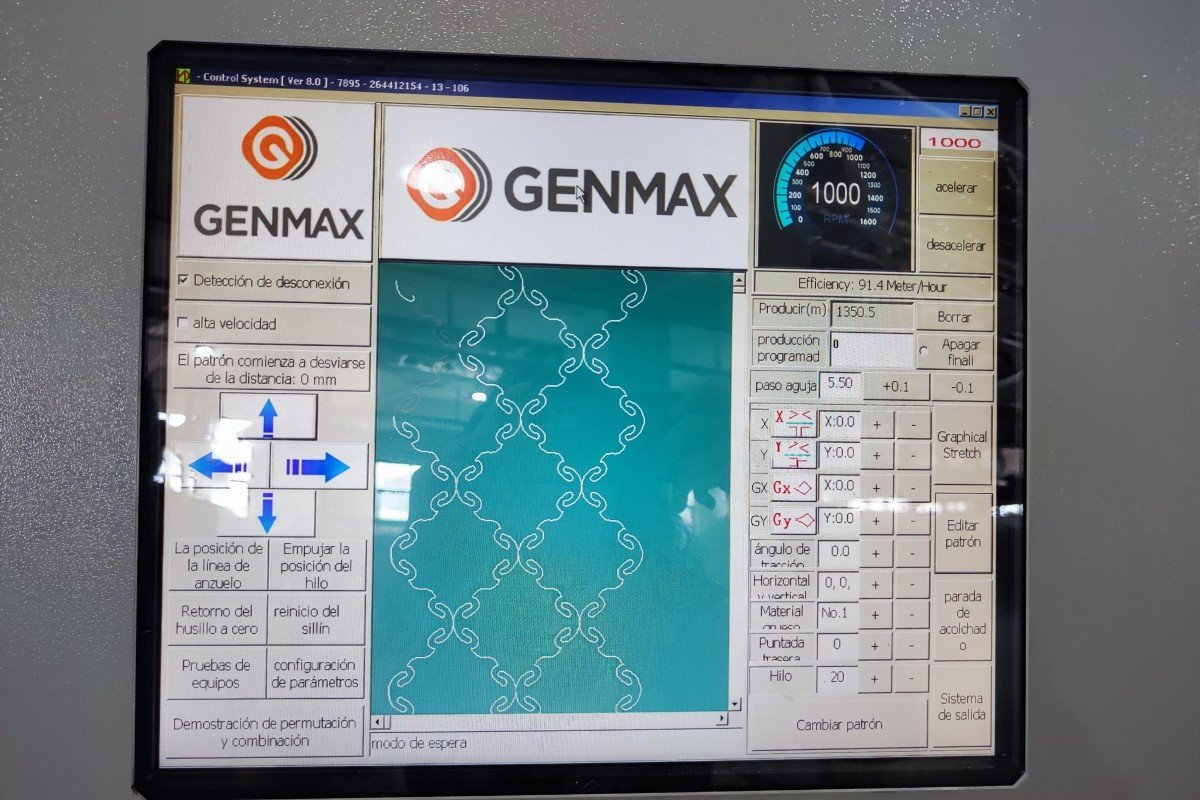

The manufacturer looked closely at build quality, maintenance access, and control systems during the evaluation. They were especially interested in our remote diagnostic capabilities, which have been highly beneficial for our South American customers.

The visitor noted the machine’s specs. They focused on how other South American textile producers used GENMAX equipment in their operations.

Close-up of the advanced quilting machine control panel featuring Spanish-language interface on the touchscreen display, allowing Latin American operators to easily program complex quilting patterns and machine settings

Building on South American Success

The Peruvian manufacturer is finishing their evaluation. They are comparing different options before making a decision. They plan to bring their production manager for a follow-up before making a choice.

“The combination of machine performance and your established support in South America makes GENMAX a strong contender,” they concluded. “Seeing how many producers here rely on your equipment gives us confidence.”

GENMAX is boosting our presence in the South American textile market. We focus on the region’s unique challenges. We offer top-notch equipment and full support. This makes us a reliable partner for textile manufacturers across the continent. They can increase production without losing quality.