Mexico Home Textile Producer Boosts Efficiency with GENMAX Ultrasonic Production Line

Is your home textile production line slow? Do you have uneven bonding or fabric damage? Old quilting and cutting methods can slow down work and affect quality. This is especially true for synthetic and non-woven fabrics.

A leading home textile manufacturer in Mexico faced these exact challenges.

They needed a quicker, cleaner, and more flexible production line for bedding, mattress covers, and home textiles.

GENMAX, a well-known mattress and textile machinery brand in South America, delivered an advanced ultrasonic production line that combines fiber processing, quilting, and precision cutting equipment. All systems were engineered and installed on-site for seamless startup.

Production Challenges Slowing Growth

- Conventional quilting with needles limited speed and caused fabric wear

- Difficulty processing synthetic, non-woven, and delicate layered fabrics

- Inefficient cutting methods that damaged edges or created burrs

- A versatile line is needed to handle many products, like bedspreads, pillowcases, sofa covers, and more

If your factory faces similar bottlenecks, this story highlights a modern solution.

GENMAX Ultrasonic Production Line: Machines Powering the Upgrade

FT300 Fiber Filling and Carding Machine

- Processes recycled polyester, wool, and fabric scraps into uniform fiber

- Production capacity: 350 kg/hour (fiber weight 80-300g)

- Prepares high-quality fiber batt for quilting and lamination

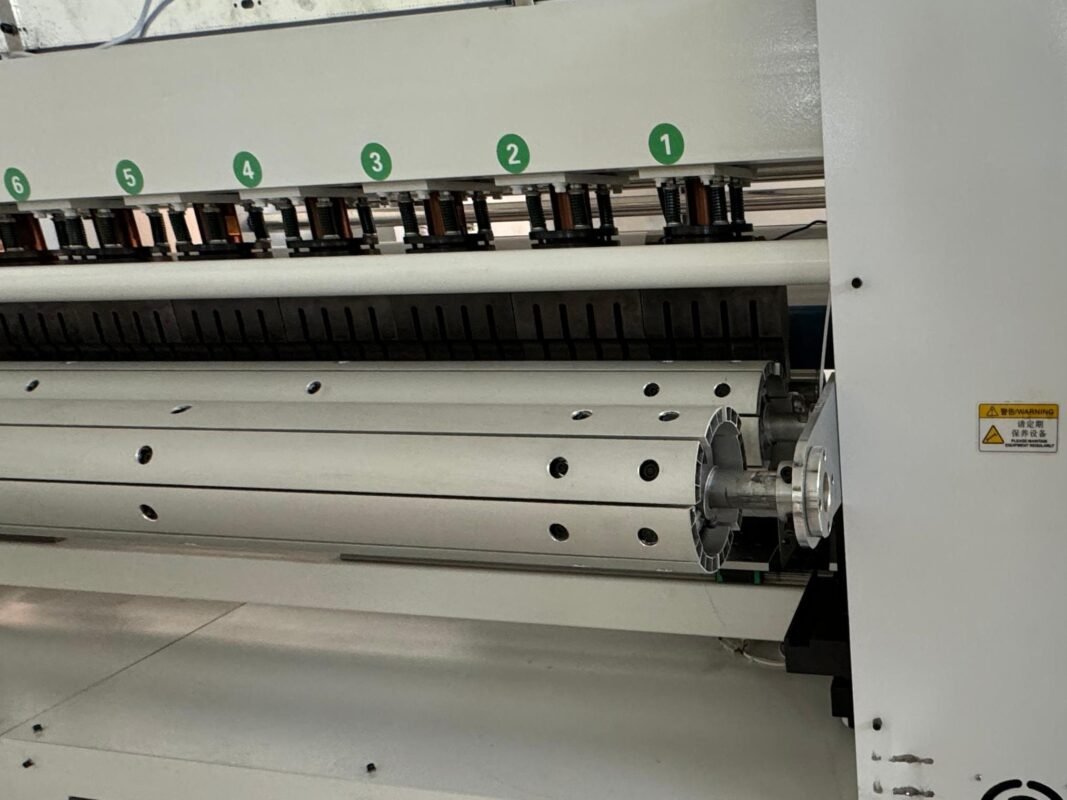

UX4 Ultrasonic Quilting Machine

- Sixth-generation intelligent ultrasonic lamination technology

- Needle-free bonding replaces traditional stitching for cleaner, stronger seams

- Production speed: 50-1200 m/h — 3 to 5 times faster than conventional quilting

- Adjustable stitch width up to 3200 mm for diverse quilting patterns

- Customizable embossing rollers (up to 19 cm diameter) for detailed designs

- Built-in slitting system with 10 precision blades for clean edges

- Comprehensive ultrasonic protection system ensures operational safety

- Handles synthetic fabrics, artificial leather, and non-woven materials

- Eco-friendly operation with no adhesives required

UCJ Ultrasonic Horizontal and Vertical Panel Cutting Machine

- Combines cutting and bonding with ultrasonic technology in one step

- Digital ultrasonic generator for superior precision and stability

- Cutting speed: 1-3 meters per minute depending on material thickness

- PLC control with touchscreen interface for easy operation

- Burr-free edges with less than 5 mm cutting error

- Edge protection technology prevents fabric damage

- Compatible with synthetic fabrics containing over 50% polyester

- Servo control and linkage compensation synchronize cutting and welding

- Advanced cooling system for continuous high-power operation

How the Line Works Together?

- Fiber Preparation: FT300 processes recycled fibers into uniform batt ready for quilting

- Ultrasonic Quilting: UX4 quickly bonds multiple fabric layers. It does this without needles or adhesives. This method creates durable and intricate quilting patterns.

- Precision Cutting: UCJ cuts and bonds fabric panels at the same time. This creates sealed edges with clean finishes, ready for assembly.

This integrated line offers quicker throughput, better quality, and reduced waste. It’s ideal for mattress covers, bedding, and other home textiles.

What GENMAX Delivered

- South American market expertise: Decades of experience helping textile and mattress factories across South America, with local service centers and technical teams for rapid response

- Expert installation: Complete on-site installation, commissioning, and testing to ensure the line met production targets from day one

- Customized solutions: Equipment configured for the client’s specific fabric types and product range

- Increased production speed: Ultrasonic quilting operates up to 5 times faster than traditional stitching, significantly boosting output

- Enhanced quality: Needle-free bonding eliminates holes and fabric damage, extending product life

- Operational safety: Ultrasonic protection systems and advanced controls minimize downtime and accidents

- Environmental benefits: Adhesive-free bonding reduces chemical use and environmental impact

- Ongoing support: Local service teams provide rapid troubleshooting and maintenance assistance

Benefits for Your Factory

If your home textile production needs improvement in speed, quality, and versatility, consider:

- Investing in ultrasonic quilting to replace needle stitching for cleaner, faster bonding

- Integrating cutting and bonding operations to reduce material handling and improve edge quality

- Partnering with suppliers who provide complete engineering, commissioning, and local after-sales support in South America

Key Considerations for Home Textile Producers

- Equipment compatibility: Can the machinery handle your fabric types and product range?

- Production speed: Will the ultrasonic quilting and cutting equipment meet your throughput requirements?

- Quality control: Are bonding and cutting operations precise and consistent?

- Support and training: Is expert installation and commissioning included?

- After-sales service: Are local technicians available for quick response in South America?

Choosing the right ultrasonic production line can transform your operations and product quality.

Client Success Snapshot: Mexico Home Textile Producer

| Metric | Before GENMAX Line | After Installation (3 Months) | Improvement |

| Quilting speed (m/hour) | 50 | 1200 | +350% |

| Cutting accuracy (edge burrs) | Frequent | None | 100% reduction |

| Product defect rate | 4.5% | 1.2% | -73% |

| Downtime due to machine issues | Moderate | Minimal | Significant drop |

Sources

- Ultrasonic Technology Association, “Advances in Textile Lamination,” 2024

- Mexico Textile Industry Report, “Trends in Home Textile Manufacturing,” 2025