Ultrasonic Quilting Embossing Machine

UM4 Ultrasonic No-Needle Quilting Embossing Compound Machine bonds chemical fiber fabrics, non-woven fabrics, and spray-bonded cotton using ultrasonic principles. Features 19 customizable sewing heads, 3200mm stitching width, multi-layer feeding racks for continuous composite quilting operation.

Download PDF

Customer Service

Share your contact information – our engineers respond 24/7.

Ultrasonic Quilting Embossing Machine Features Overview

High Productivity

Simple Operation

Highly Automatic

Needle-Free

Built-In Slitting System

Eco-Friendly

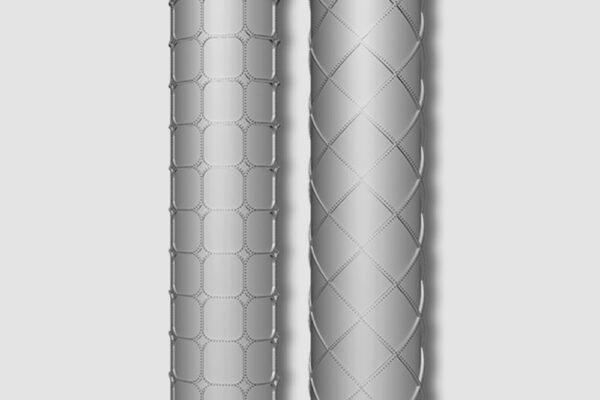

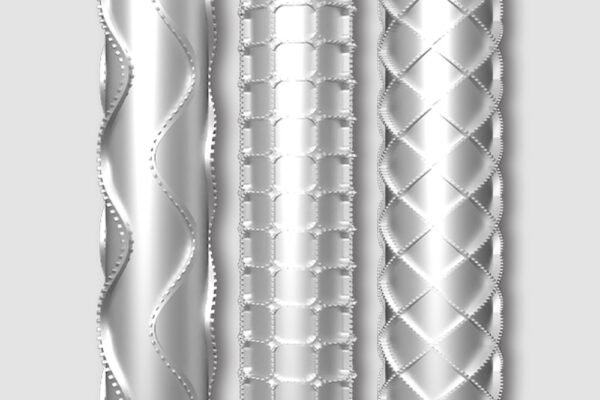

Embossing Roller

Technical Specification

|

Working Speed |

50-1200m/h |

Max Thickness |

60mm |

|

Roller Width |

1850/2300/2600/2907/3060mm |

Horn |

19 sets(depends on width) |

|

Slitting Knife |

12 pieces(depends on width) |

Diameter of Roller |

130-190mm(Customized) |

|

Roller Pattern |

Can Be Customized |

Roller Type |

Engraving 4-7mm |

|

Working Frequency |

18khz |

Weight |

2000kg |

|

Motor Power |

9KW(instantaneous current 18kw) |

Power |

380V,3P,50HZ |

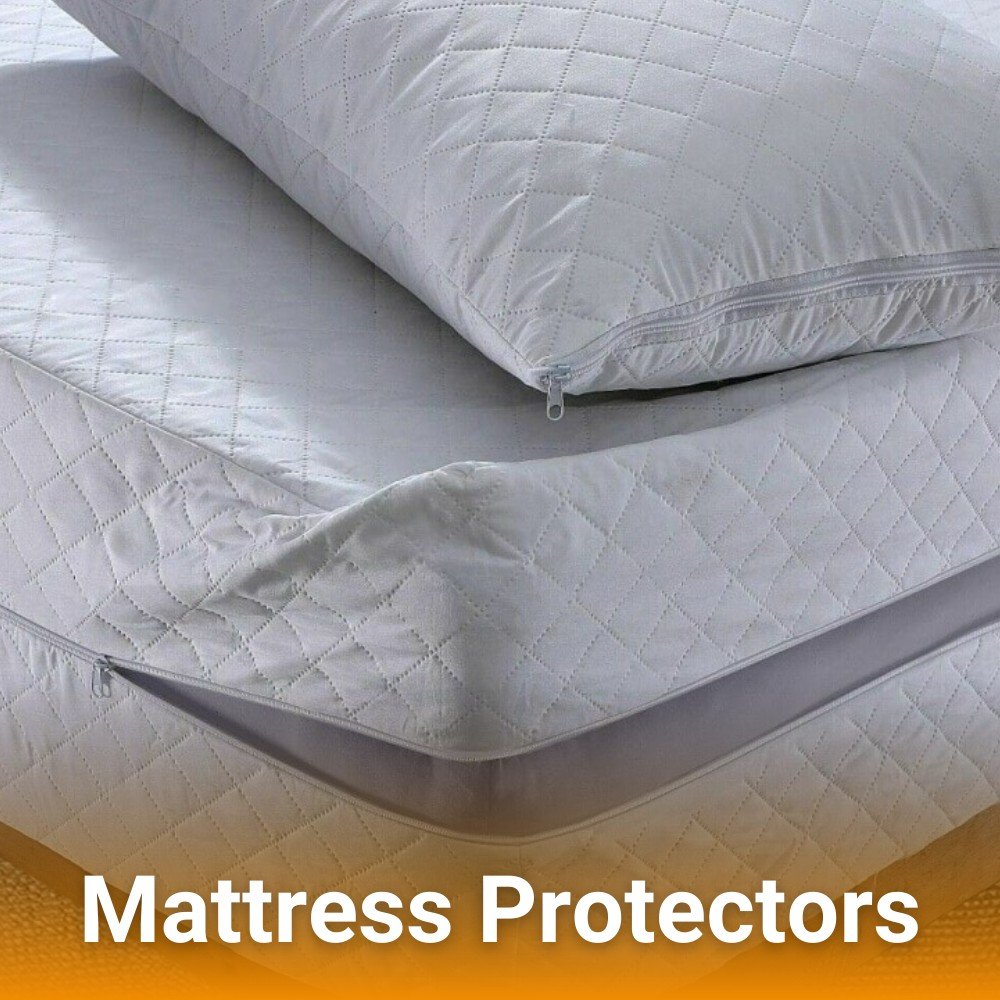

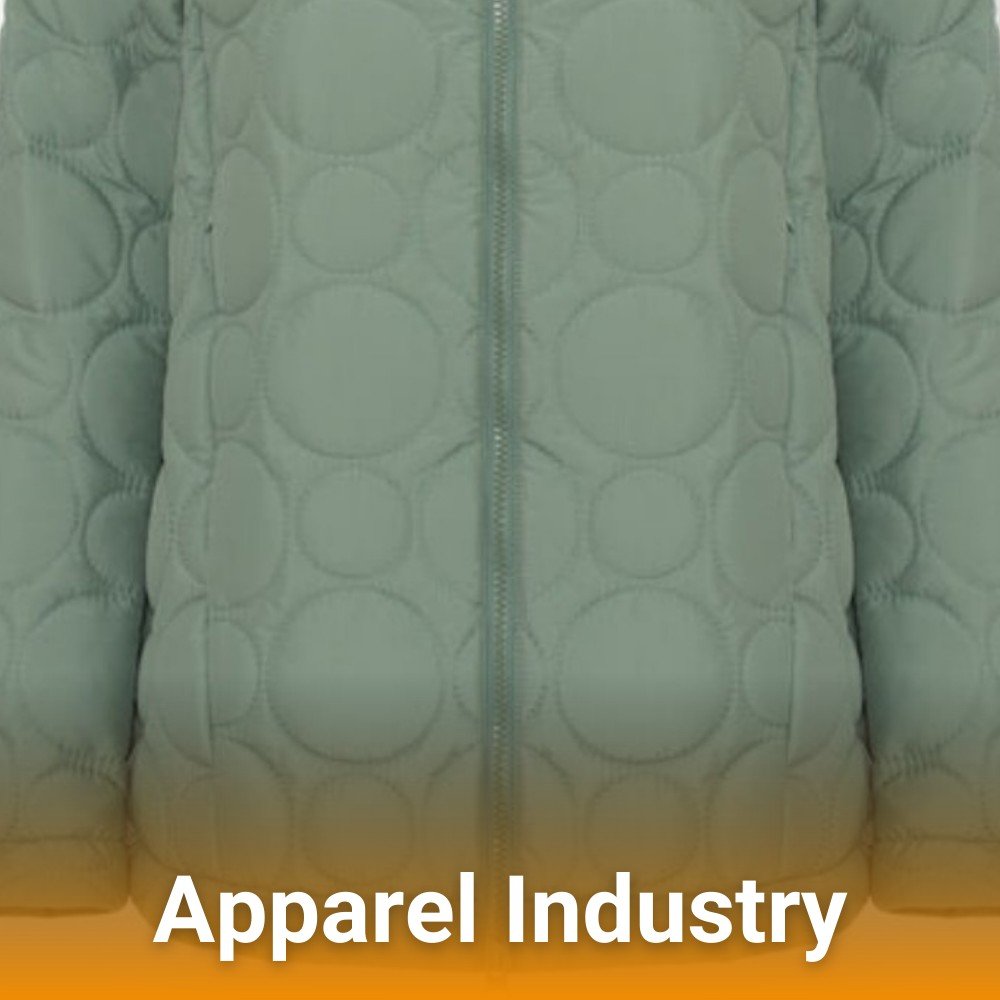

Applications of Ultrasonic Quilting Embossing Machine

What Our Customers Say

Uzbek Mattress Maker Finds Perfect Fit with GENMAX Ultrasonic Quilter

GENMAX Ultrasonic Quilting Machine Impresses Mexican Visitor

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Most Popular Questions

The UX4 offers high production efficiency with working speeds of 50-1200 meters per hour, which is 3 to 5 times higher than traditional needle and thread quilting machines.

Different patterns are created by changing the pattern rollers. The pattern of the rollers can be customized according to requirements, allowing for flexible design options.

The maximum thickness the machine can process is 60mm (1000gsm).

Yes, the UX4 comes with a slitting device with precise kinetic energy for cutting 4 sides. The machine comes standard with 10 blades.

The UX4 is ideal for the bonding of various types of chemical fiber fabrics. It may not be suitable for all natural fabrics, as ultrasonic bonding works best with synthetic materials.

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Recommend

Lock Stitch Shuttle Multi Needle Quilting Machine

Download PDF

Multi Needle Chain Stitch Quilting Machine

Download PDF

Single Needle Continuous Quilting Machine

Download PDF