Ready to Make Our Mark: GENMAX’s Final Preparations for CIFF 2025

We’re almost there! With just 5 days until CIFF begins in Guangzhou, our warehouse is a flurry of activity. Machines are fine-tuned. Marketing materials are ready. Our tech team is testing all we’ll showcase.

Why This Year Feels Different

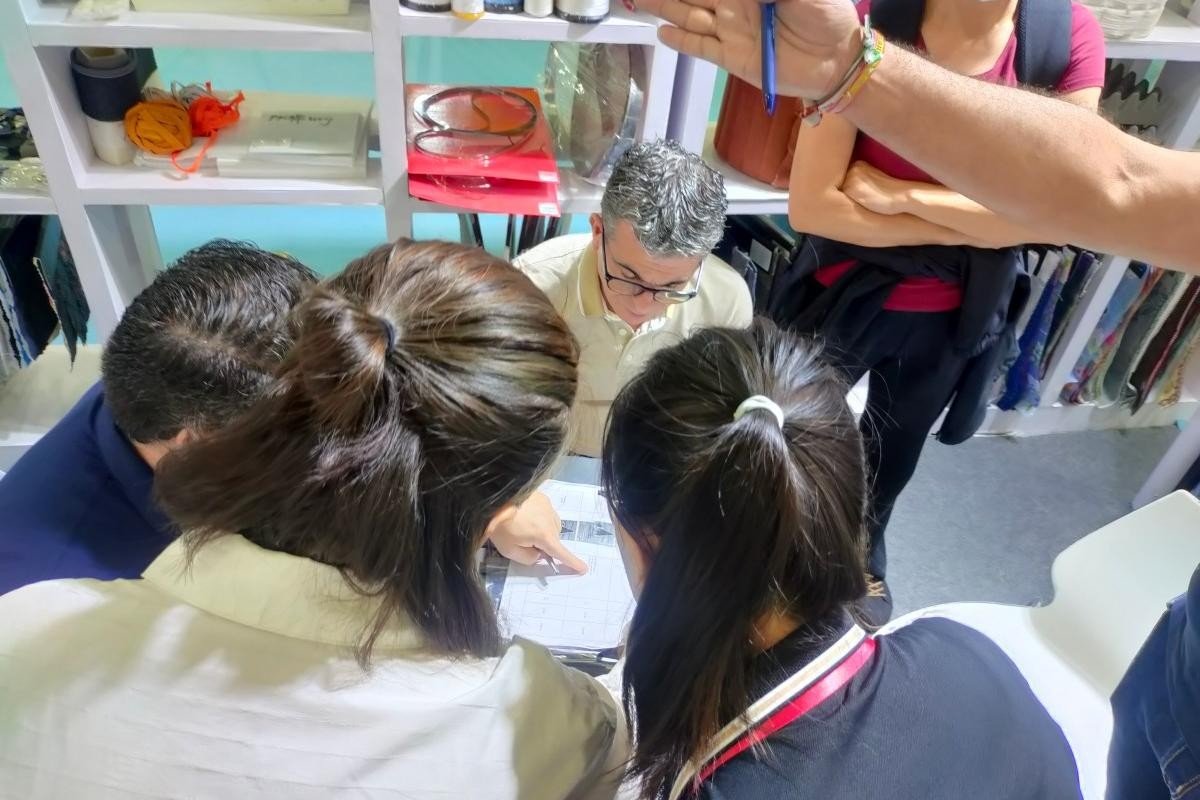

I’ve guided GENMAX through eight CIFF exhibitions, but this year feels unique. Maybe it’s the 14 months we spent on the EM122 upgrades. Or perhaps it’s the talks with mattress manufacturers facing tough production issues.

“We’re not just bringing machines to Guangzhou,” our production manager told me yesterday while adjusting the UM300. “We’re bringing solutions to problems our customers can’t even describe yet.”

What We’re Bringing to Booth S12.1 B31

If you visit us from March 28-31, here’s what you’ll see:

- EM122 Embroidery Machine: We redesigned the thread handling system, cutting downtime by 37% in tests.

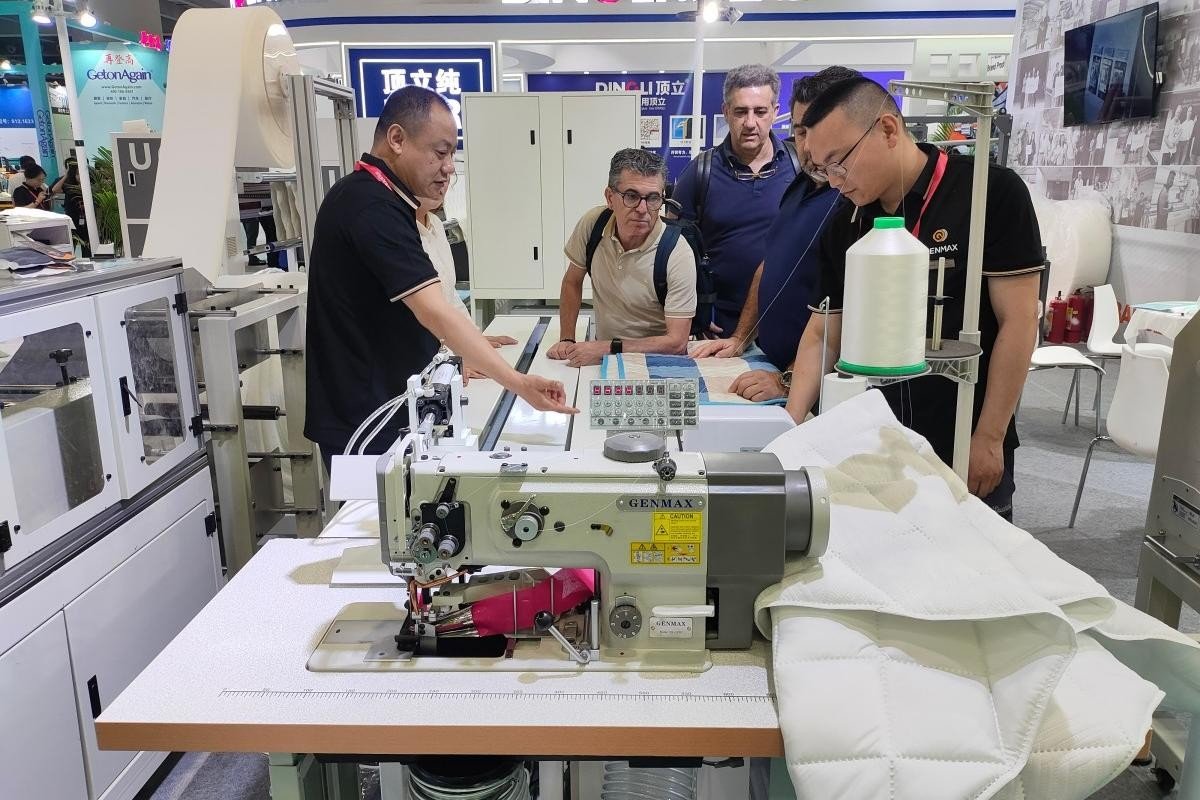

- UM300 Ultrasonic Border Machine: This new version cuts production time and keeps edges consistent. Our competitors find this challenging.

But specs only tell part of the story. We’ve set up the booth for you to run test pieces yourself. No barriers, no “please don’t touch” signs. This machinery is meant to be used, not just admired.

The Market Challenges We’re Addressing

Last month, I visited three factories in Spain. The managers shared a common problem with me: inconsistent border seams when running at full capacity. Their machines can’t maintain precision for more than 6 hours.

We designed the UM300 to fix this. At CIFF, we’ll run 8-hour demos to show it keeps calibration where others fail.

For Those Who Can’t Make It

While nothing beats seeing machinery in action, we know international travel is tough for many customers. If you can’t join us in Guangzhou, reach out. We’re scheduling private virtual demos throughout April.

With shipping containers of equipment heading to the exhibition center next week, it’s go-time for our team. We’re ready to show what GENMAX can do and prove why we set the standard in mattress machinery innovation.