Automatic Mattress Wrap Compress and Roll Pack Line

The AMC-620 is an automatic mattress packing line offering wrap, compress, fold, and roll capabilities in one compact unit. Its unique design enables multiple operation modes without additional conveyors, significantly reducing shipping and storage costs while maximizing profit.

Download PDF

Customer Service

Share your contact information – our engineers respond 24/7.

Automatic Mattress Wrap Compress and Roll Pack Line Features Overview

Fully Automatic Operation

Technical Specification

|

Capacity |

35 seconds per mattress |

Apply To Mattress Type |

Spring, Foam, Latex |

|

Max. Mattress Size |

220 cm x 220 cm |

Min. Mattress Size |

180 cm x 75 cm |

|

Max. Mattress Height |

45 cm |

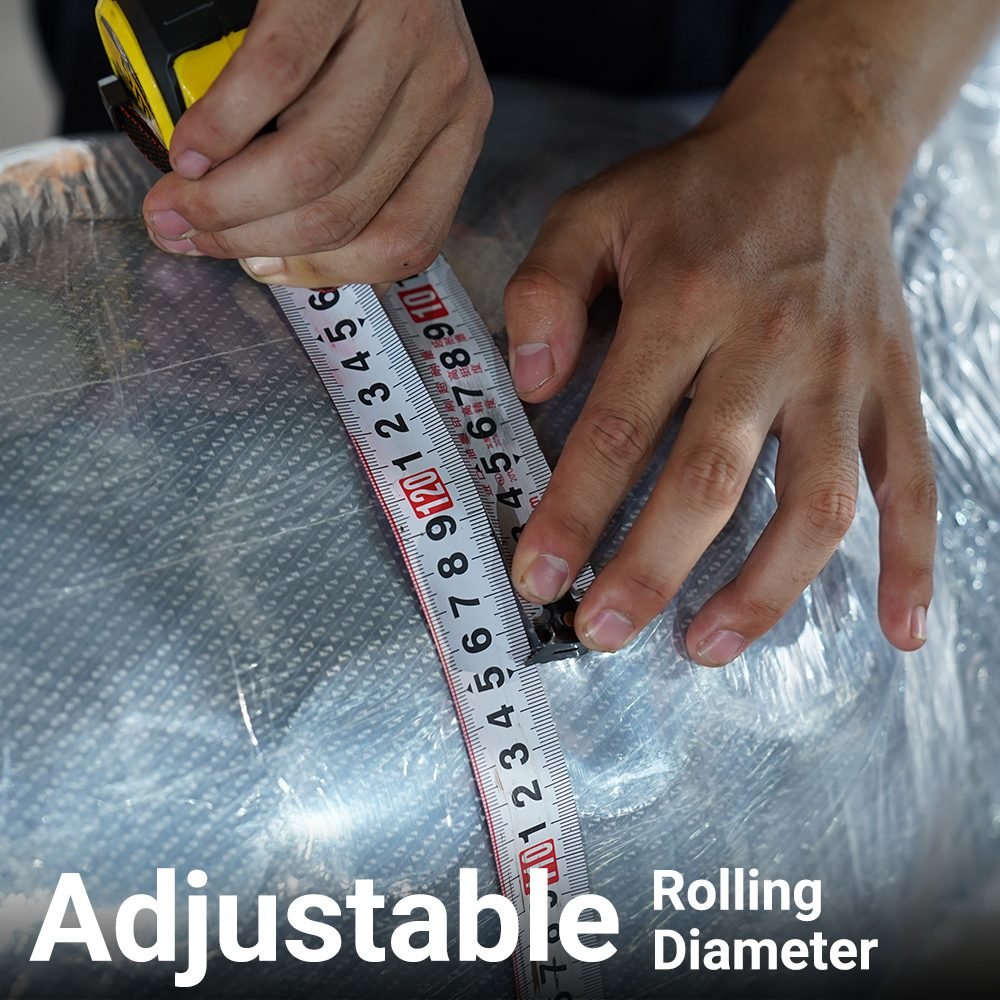

Exit Diameter of the Mattress |

23-62cm Adjustable |

|

Max. Pressure Load |

80 Tons |

Packaging Material at the Roll Cage |

Stretch or PE Film |

|

Air Consumption |

≥0.43 m³/min;12mm air pipe |

Air Supply |

0.6-0.8Mpa |

|

Weight |

14,000 kg |

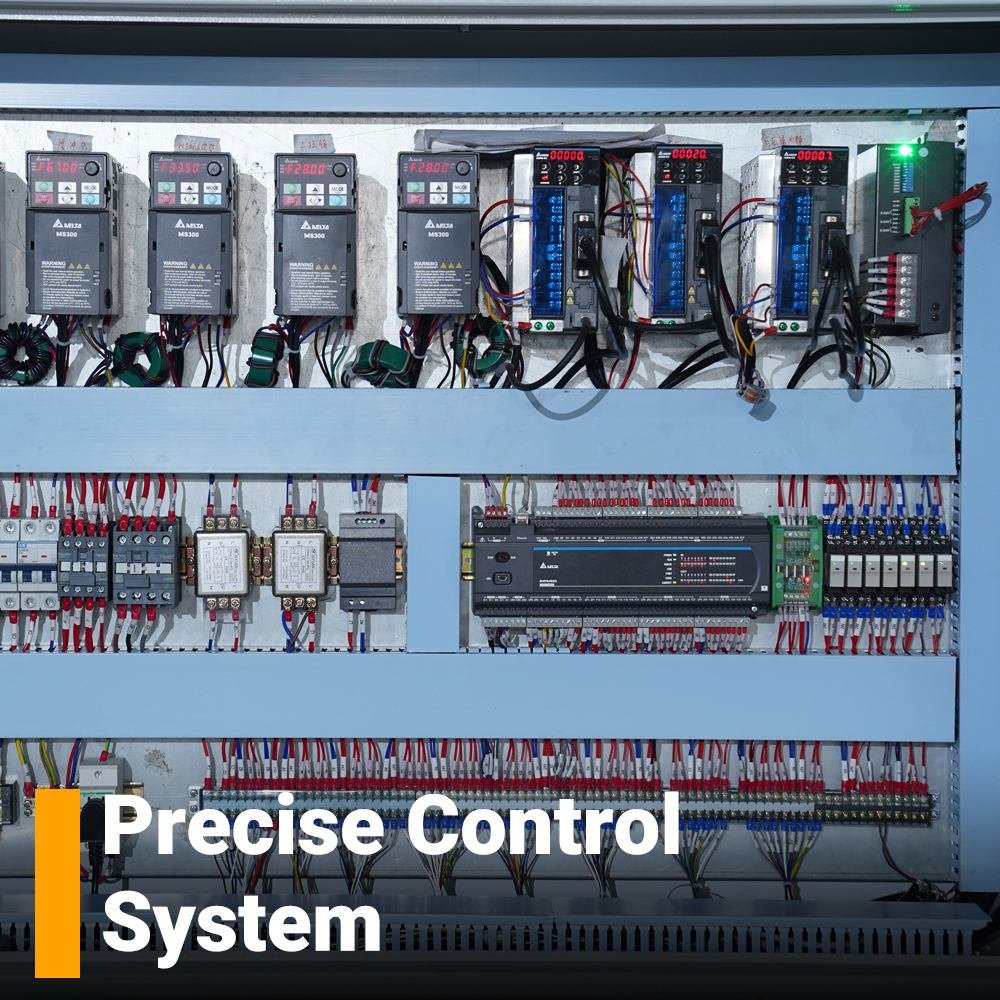

Power Requirement |

43KW/45KW is for two packaging ways |

|

Voltage Type |

3Phase AC380V 50HZ |

Compressed Air |

6-7 Bar |

What Our Customers Say

35-Second Packaging Cycles: GENMAX Accelerates Korean Mattress Production

Saudi Manufacturers Cut Packaging Costs 60% with GENMAX AMC-620

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Most Popular Questions

Its unique design allows all operating modes to work on a single station without requiring additional turning or 90° transfer conveyors, offering the smallest footprint compared to competing machines.

The machine has a cycle time of up to 35 seconds per mattress.

The AMC-620 features a 80-ton hydraulic adjustable compression unit, making it one of the heaviest duty compression machines in the market.

The machine can pack and roll various mattress types including:

Pocket spring mattresses

Bonnel spring mattresses

Foam mattresses

Latex mattresses

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Recommend

Mattress Tape Edge Machines FB Series

FB Series Tape Edge Machines deliver high-speed sewing for all mattress types with exceptional flexibility and precise tape edge application. Built with ergonomic design combining operator comfort with maximum efficiency for reliable manufacturing productivity across any mattress style.

Download FB3 PDF

Download FB5 PDF

Profile Foam Cutting Machine

Download PDF

Single Needle Frame Type Mattress Quilting Machine

Download PDF