Multi Needle Chain Stitch Quilting Machine

MX-Multi Needle Chain Stitch Quilting Machine features automatic thread breakage detection, simple maintenance, and clear needle alignment display. High-speed processing with low vibration delivers precise quilting for mattresses, household ornaments, and carpet cushions through advanced sewing technology.

Download PDF

Customer Service

Share your contact information – our engineers respond 24/7.

Multi Needle Chain Stitch Quilting Machine Overview

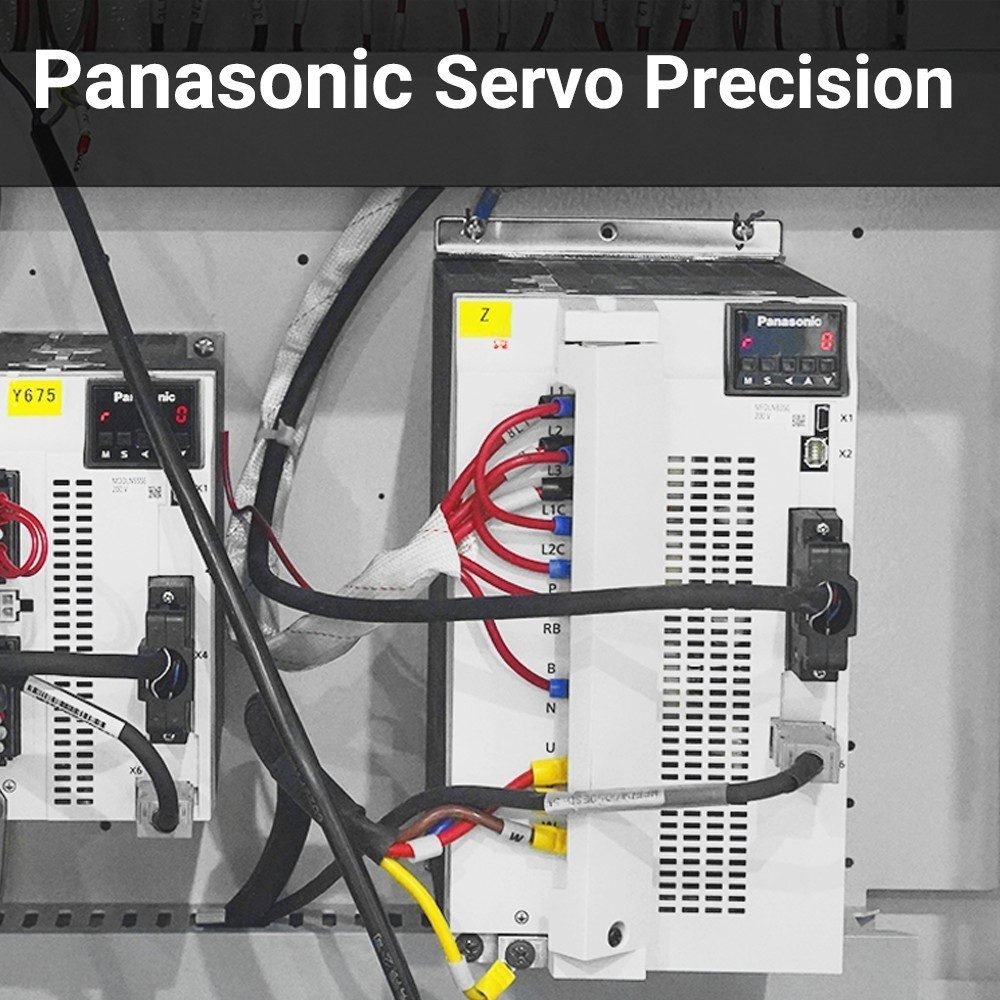

Panasonic Servo Precision

360° Tack-and-Jump Quilting

Auto Thread Break Detection

Slitting Devices

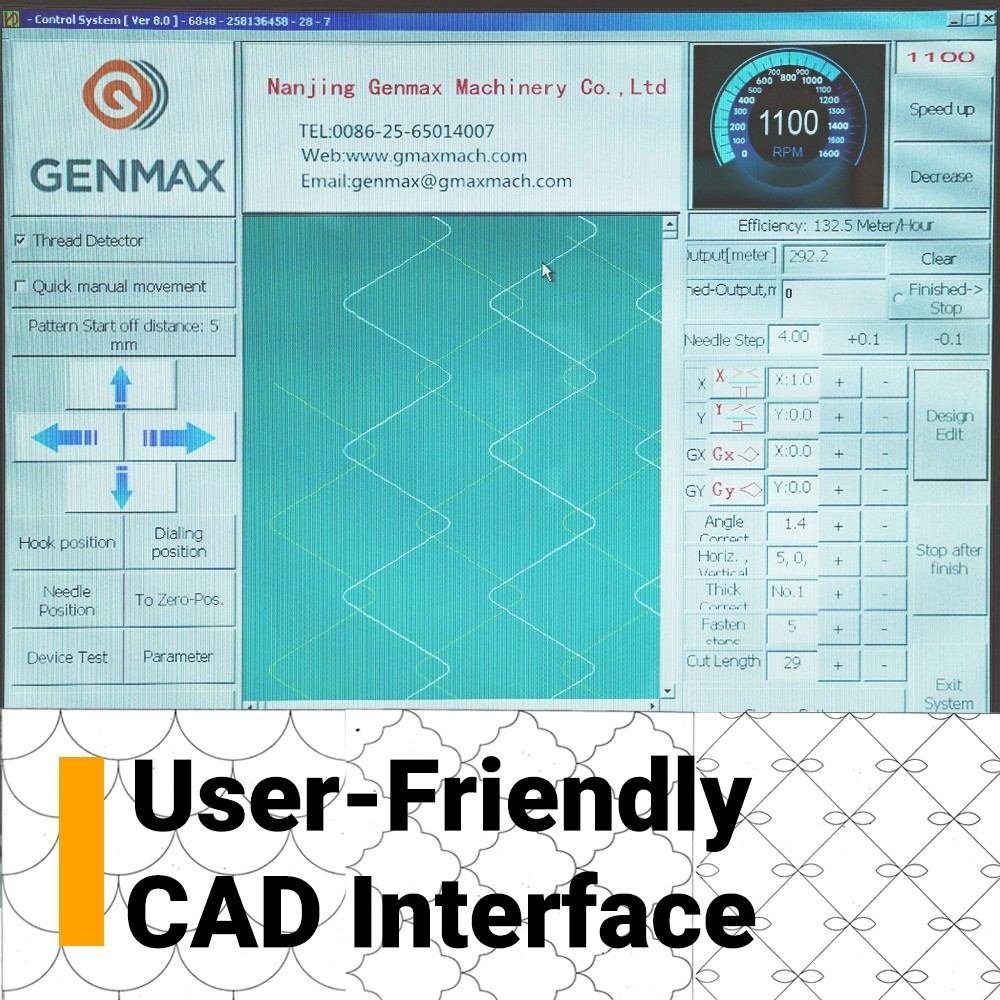

User-Friendly CAD Interface

Double-swinging Needle Bar

Multi Needle Chain Stitch Quilting Machine Specification

|

MODEL |

MX7 |

MX6 |

M5 |

M4 |

|---|---|---|---|---|

|

Main Shaft Speed |

1400RPM |

600-1300RPM |

600-1200RPM |

|

|

Output |

Re-model of Domestic Head |

KINFTEX |

JUKI 6900---6916 |

PEGASUS |

|

Model Of Needle |

12mm |

15mm |

15mm |

15mm |

|

Space Between Needle Rows |

4thread |

4thread |

5thread |

4thread |

|

Stitch Length |

Pressfoot |

Pressfoot |

Belt |

Pressfoot |

|

Space Between Needles |

600W |

550W |

550W |

550W |

|

Quilting Width |

25mm |

15/25/30/35mm |

25mm |

15/25/30mm |

|

Quilting Thickness |

0.4-0.8Mpa |

0.4-0.8Mpa |

0.4-0.8Mpa |

0.4-0.8Mpa |

|

Stroke |

Double Bar |

Double Bar |

Double Bar |

Double Bar |

|

Power Supply |

3000RPM |

3000RPM |

3000RPM |

3000RPM |

What Our Customers Say

GENMAX Drives Spain’s Mattress Quality Forward

Mexican Mattress Quality Meets North American Standards with M5 Quilter

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Most Popular Questions

The machine creates Jump, Continuous, and Striped patterns with a versatile pattern system. It offers three pattern functions with easy switching and 360° free quilting capability.

The machine includes comprehensive fault detection functions for both upper and bottom thread breaks, automatic stop motion control with immediate response to thread breakage, and emergency safety devices for operator protection.

All machine uses servo-driven technology with a 6kW Panasonic servo motor for precise control.

Yes, optional slitting devices with a saddle pendulum mechanism are available for precise cutting.

Stronger, more durable mattresses

Smooth, professional-looking edges

Faster production with automation

Lower labor costs and fewer errors

Flexibility for different fabrics and stitch types

- Mattress size range you produce

- Desired flange width and stitch type

- Production volume (small vs. large scale)

- Features needed (corner sewing, programmable patterns, etc.)

- Maintenance and ease of operation

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Recommend

Mattress Tape Edge Machines FB Series

FB Series Tape Edge Machines deliver high-speed sewing for all mattress types with exceptional flexibility and precise tape edge application. Built with ergonomic design combining operator comfort with maximum efficiency for reliable manufacturing productivity across any mattress style.

Download FB3 PDF

Download FB5 PDF

Profile Foam Cutting Machine

Download PDF

Single Needle Frame Type Mattress Quilting Machine

Download PDF