Mattress Panel Hemming Machine

The CJS panel hemming system revolutionizes mattress panel production by integrating cutting and four-side overlock sewing into a single, fully automated process. Designed to replace the labor-intensive flanging operation, it delivers precise panel sizes with 2–4% quilting material savings by eliminating waste at cross cuts and edges. Featuring adjustable presser foot, advanced digital controls, and compatibility with existing multineedle quilting machines, the system ensures consistent quality and fluffy tape edging without skipped stitches.

Get Free Consultation!

We are ready to answer right now! Sign up for a free consultation.

I consent to the processing of personal data and agree with the user agreement and privacy policy

Mattress Panel Hemming Machine Features Overview

Adjustable Presser Foot

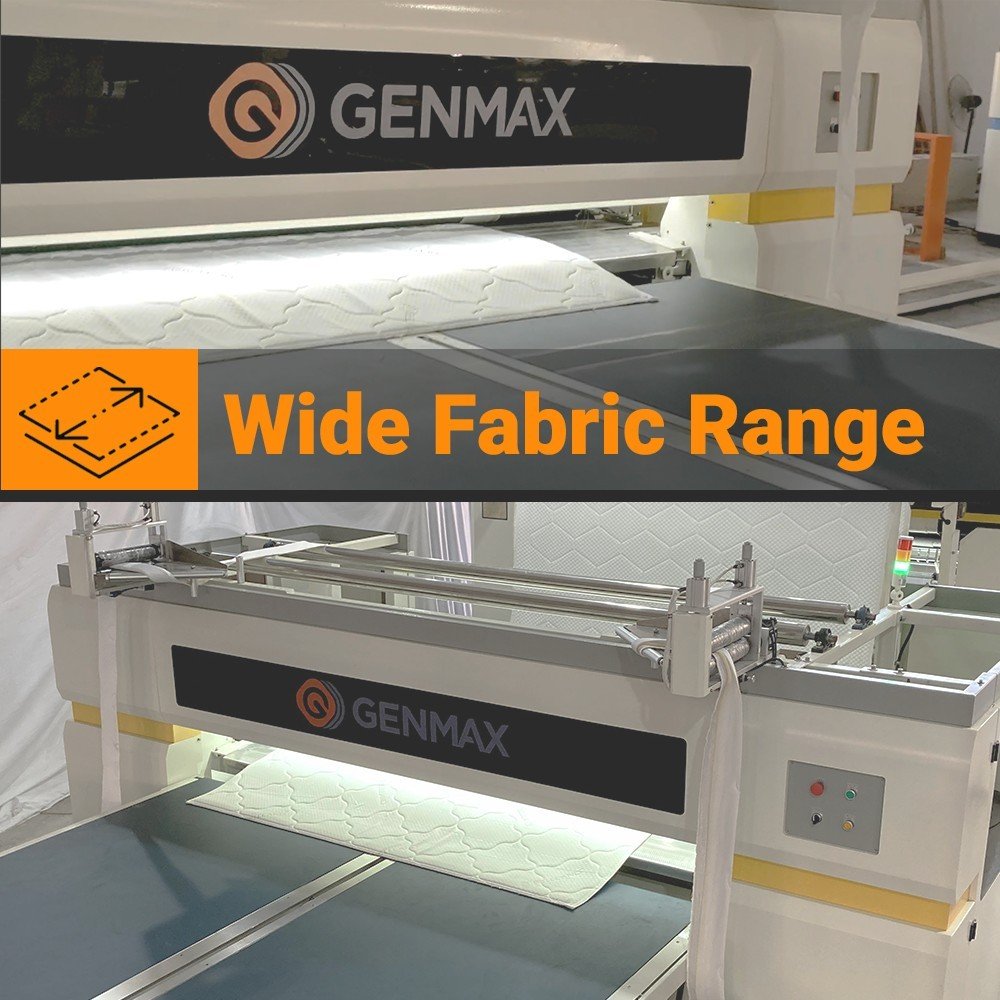

Wide Fabric Range

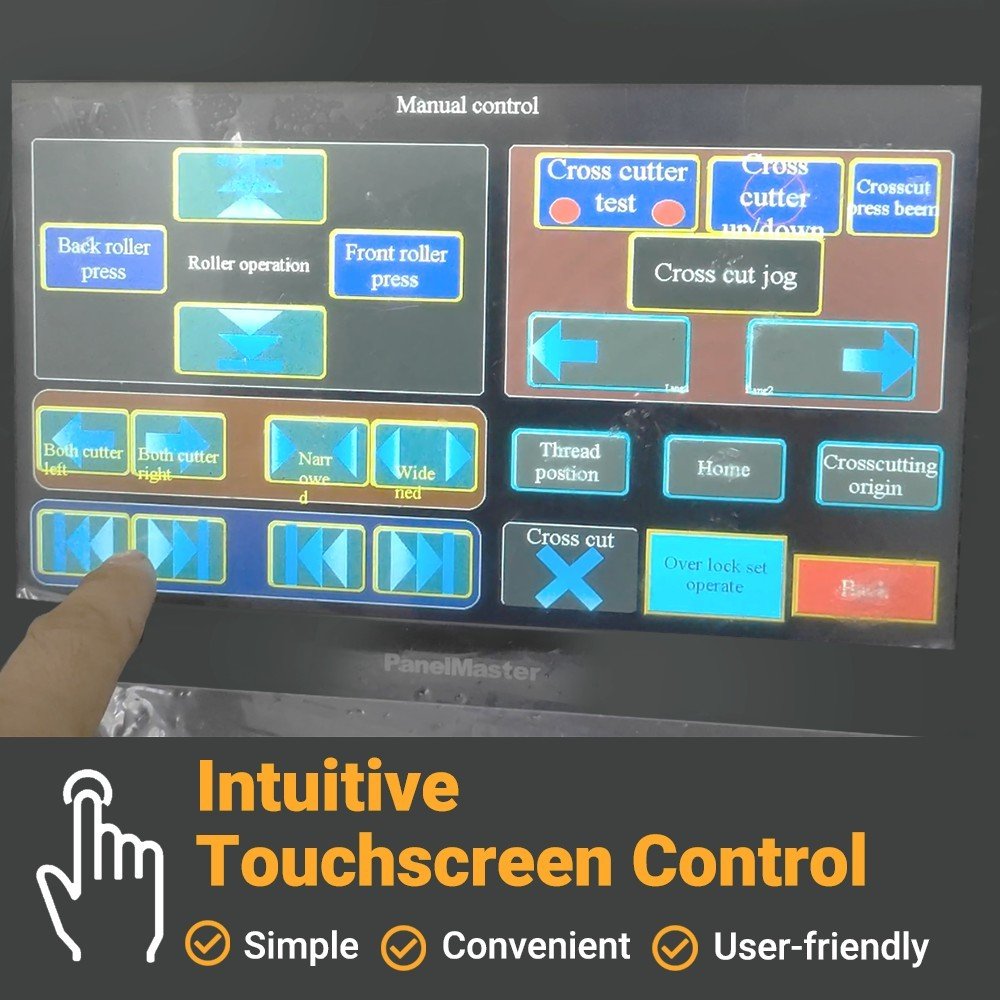

Intuitive Touchscreen Control

Mattress Panel Hemming Machine Technical Specification

|

Dimension(L*W*H) |

3235*4065*2035mm |

Sewing Width |

1000-2400mm |

|

Maximum Sewing Thickness |

≤80mm |

Stitch Length |

3-12mm |

|

Power |

10KW |

Gross Weigtht |

28000kg |

|

Voltage |

380/220V,3P,50/60Hz |

Production Speed |

2-3pcs/min |

What Our Customers Say

GENMAX Drives Spain’s Mattress Quality Forward

Nepal’s Mattress Makers Upgrade with GENMAX Quilting Machine

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Most Popular Questions

Yes, it supports multiple work orders with different sizes simultaneously.

Yes, it efficiently processes pre-quilted rolls.

Yes, it can adapt to any existing multineedle quilter.

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Recommend

Mattress Tape Edge Machines FB Series

The Base Machine for Every Mattress Producer!

GENMAX Mattress Machinery proudly presents the FB Series, designed with one goal: to provide mattress manufacturers with robust, high-speed tape edge machines that deliver years of reliable service.

The FB Series machines excel at simplifying the sewing process for all mattress types. Their exceptional flexibility allows for precise tape edge application on any mattress style. Built with ergonomics in mind, these machines combine operator comfort with maximum efficiency, helping you achieve the highest productivity levels in your manufacturing process.