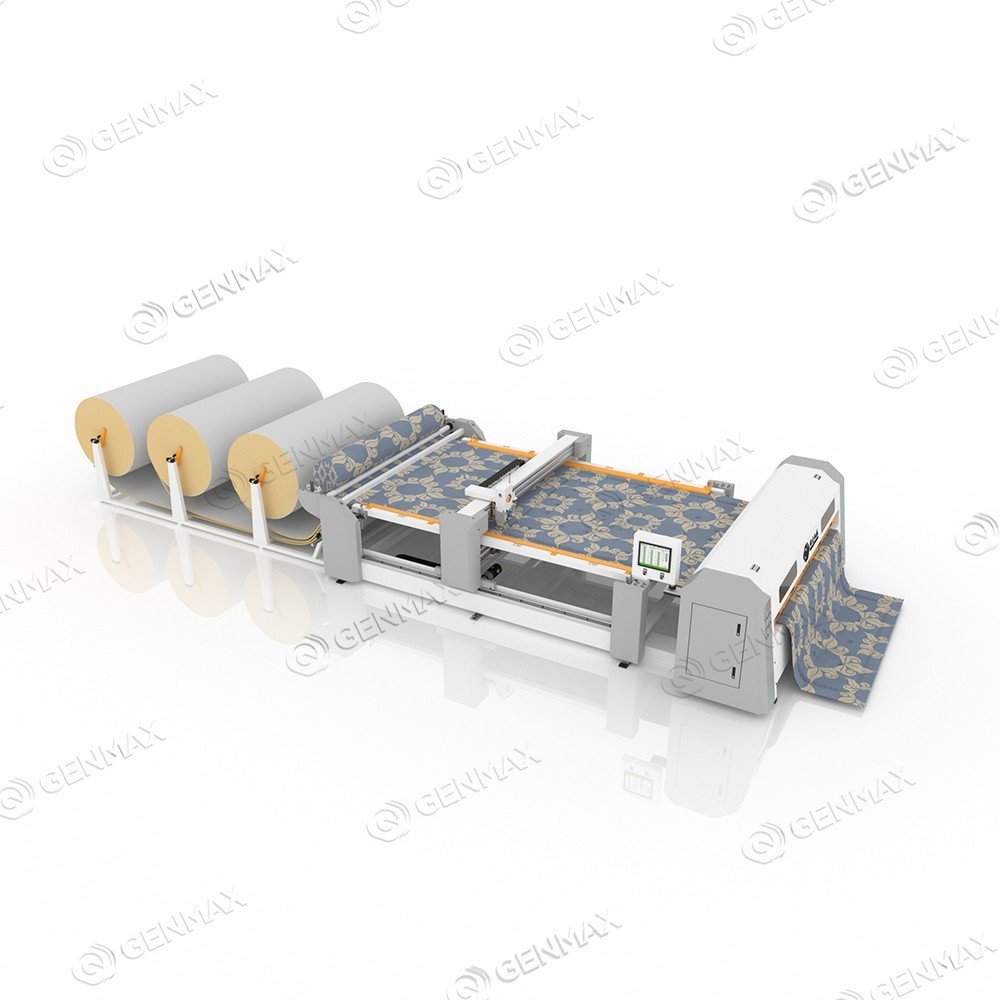

Single Needle Continuous Quilting Machine

DZ5 is a full automatic feeding system high speed single needle quilting machine for high end luxury mattress, home textile and upholstery works. DZ5 performs the whole operations of feeding with motorized rollers, quilting and cutting the quilt in length.

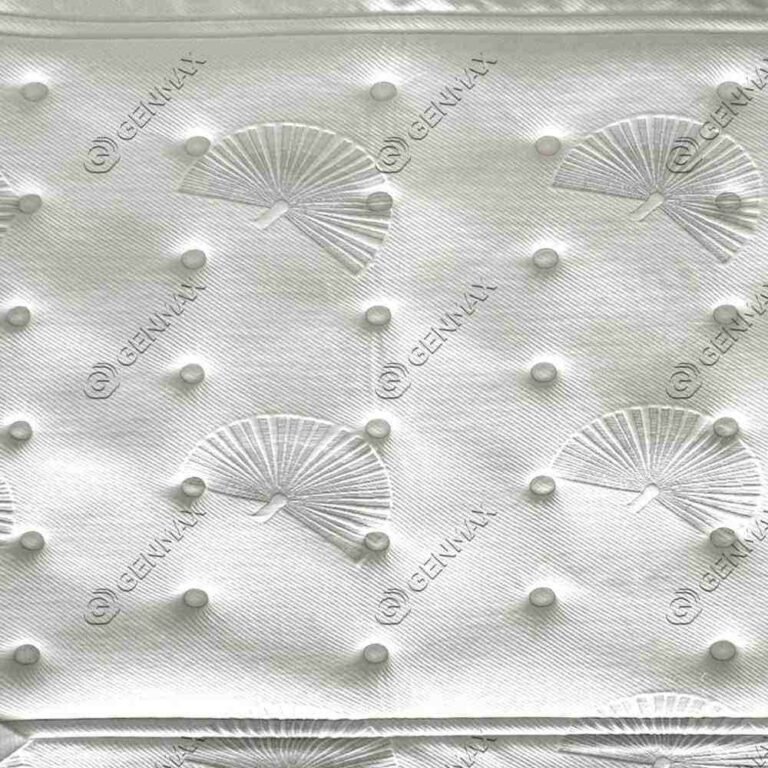

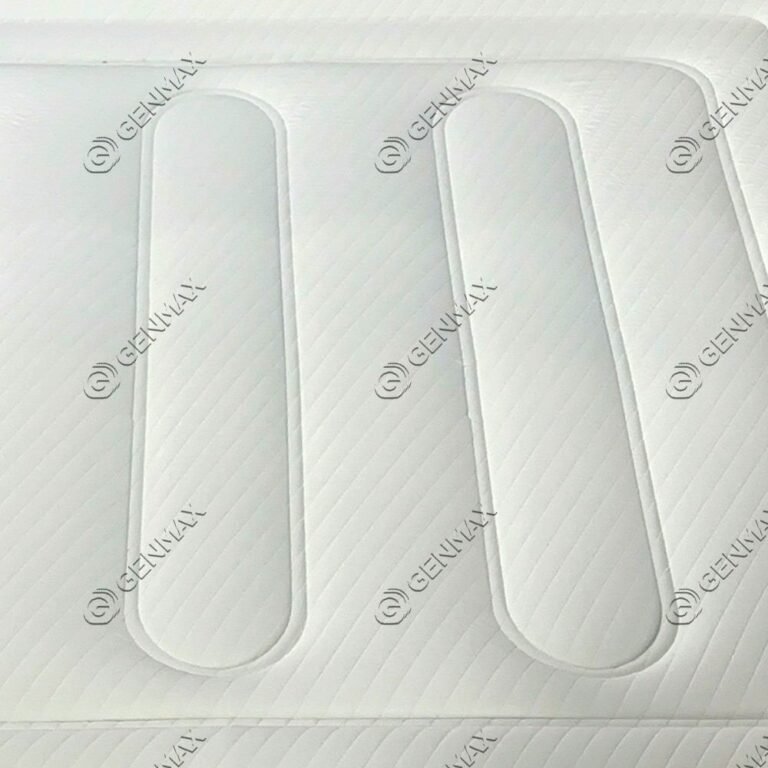

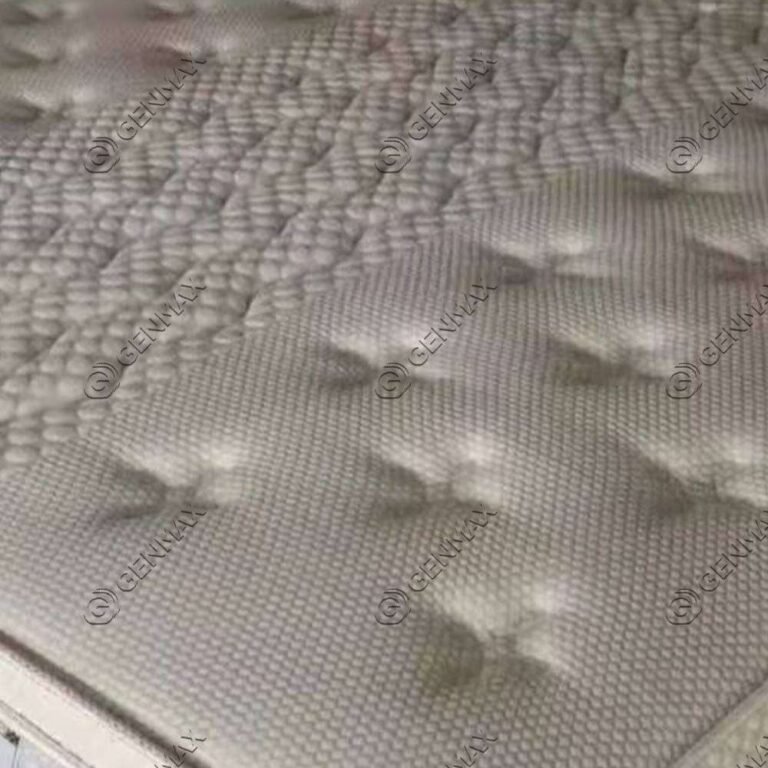

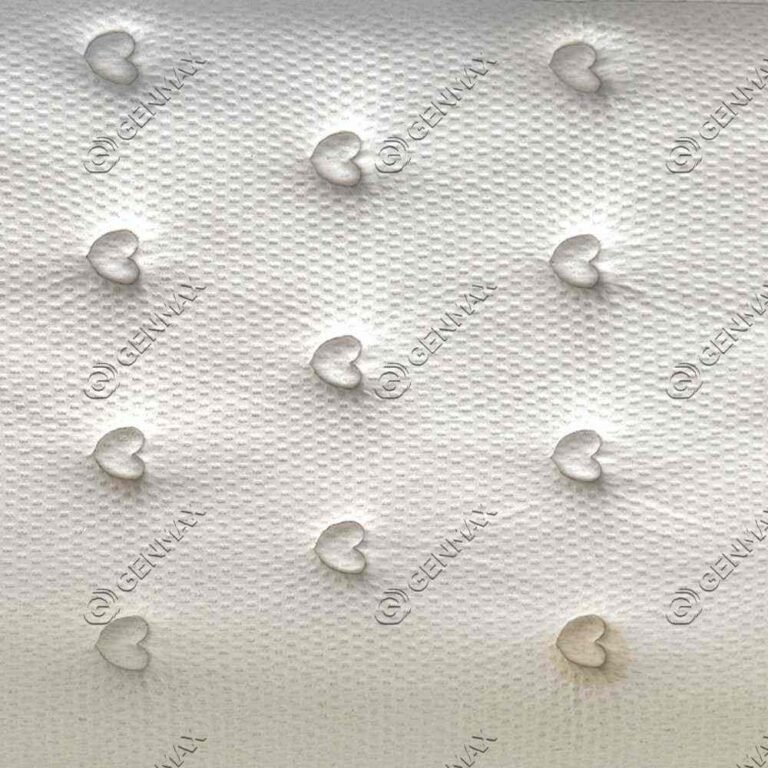

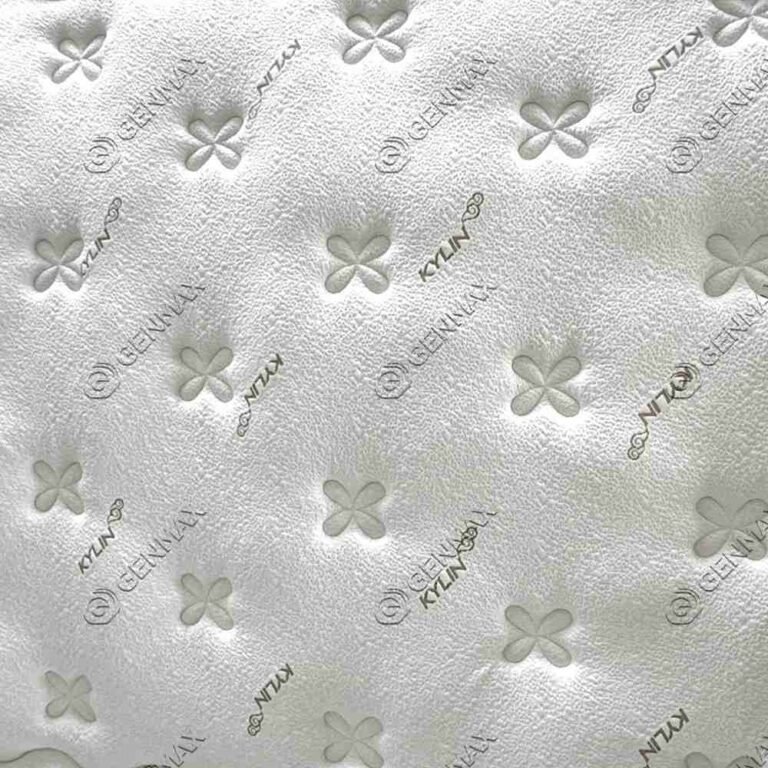

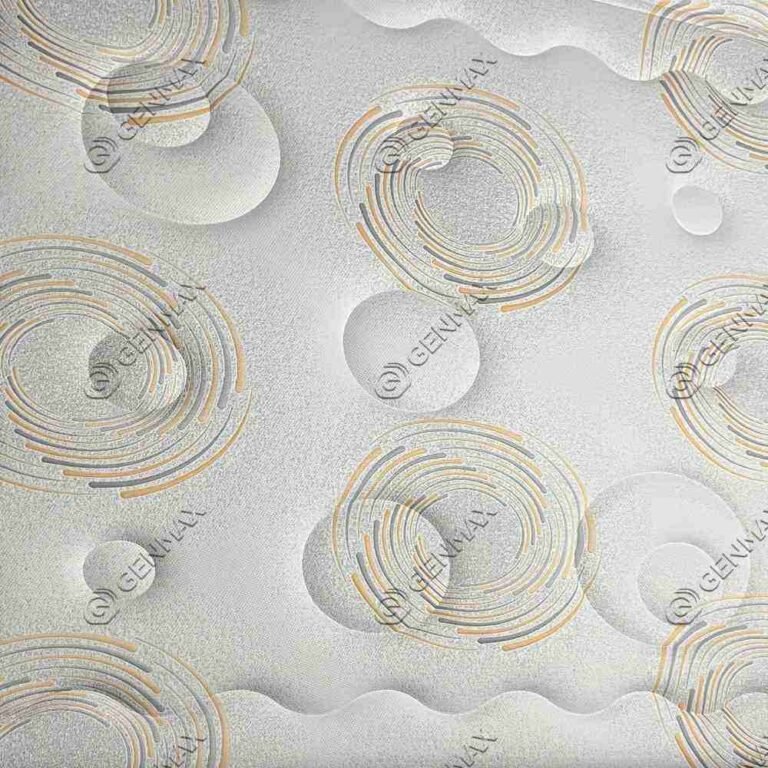

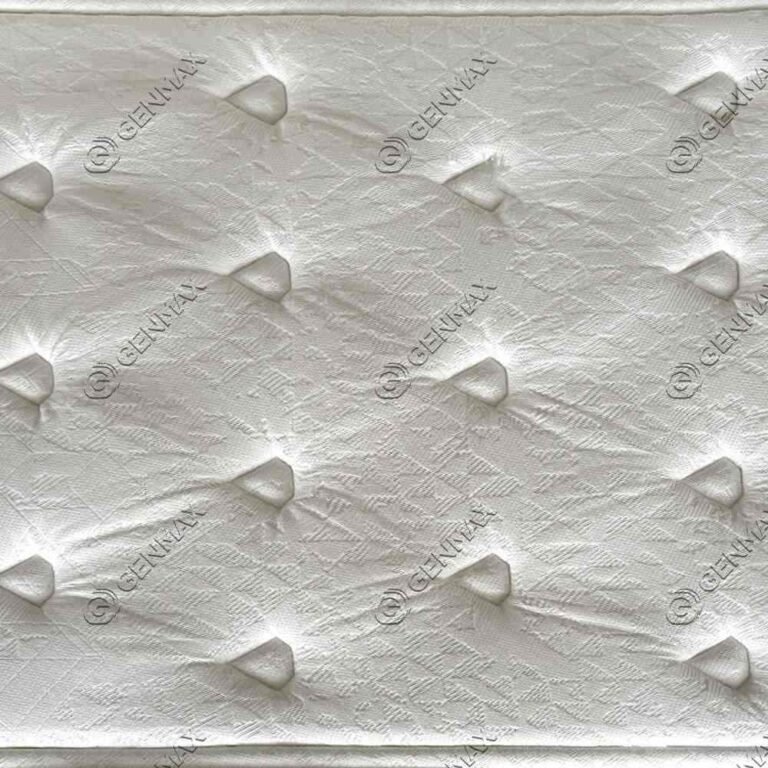

With the ability of quilting very different products, DZ5 offers perfect quilting quality for all the products from very thin garment products to thick materials for mattress industry with multiple layers including foam, visco, memory foam, latex, polyester fiber, non woven, jacquard fabric, knitted fabric, leather and down fill.

Your mattresses, headboards, comforters will overtop among others with the aspects of stitch quality, pattern designs, sustaining quality as well as your efficiency.

Download PDF

Customer Service

Share your contact information – our engineers respond 24/7.

Single Needle Continuous Quilting Machine Features Overview

|

Quilt Thickness |

≤80mm |

Quilt Width |

≤2400mm |

|

Rotation Speed |

3000rpm |

Production Speed |

70-200m/h |

|

Stitch |

2-6mm |

15mm |

15mm |

|

Power |

8.0kw |

Over all weight |

3000kg |

|

Overall(Lx WxH) |

9900x3800x1600mm |

(AC)Rated voltage |

380v/220V 50Hz/60Hz |

What Our Customers Say

Elevate Mattress Edge Quality in Portugal with GENMAX FB5

How a Mexican Mattress Startup Boosted Production and Quality with GENMAX FB3

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Most Popular Questions

DZ5 handles everything from very thin garment fabrics to thick, multi-layer mattress materials, including foam, latex, polyester, nonwoven, jacquard, knitted, leather, and down fill.

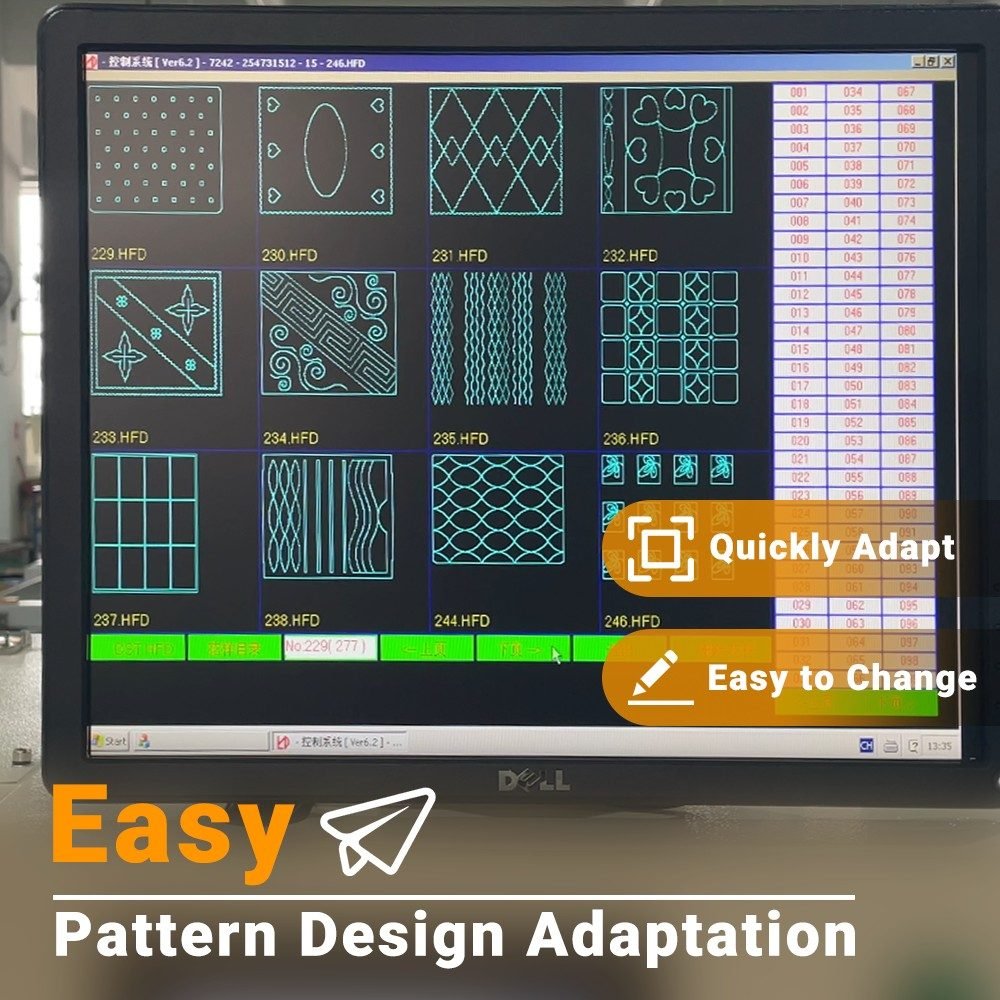

Yes, the system allows for rapid pattern changes and stitch length adjustments to meet diverse design requirements.

DZ5 features automatic park positioning, stopping and parking safely when the top or bottom thread is finished to prevent defects.

It ensures continuous, precise material handling, reduces manual labor, and minimizes downtime for material changes.

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Recommend

Mattress Tape Edge Machines FB Series

FB Series Tape Edge Machines deliver high-speed sewing for all mattress types with exceptional flexibility and precise tape edge application. Built with ergonomic design combining operator comfort with maximum efficiency for reliable manufacturing productivity across any mattress style.

Download FB3 PDF

Download FB5 PDF

Profile Foam Cutting Machine

Download PDF

Single Needle Frame Type Mattress Quilting Machine

Download PDF