Vertical Foam Cutting Machine

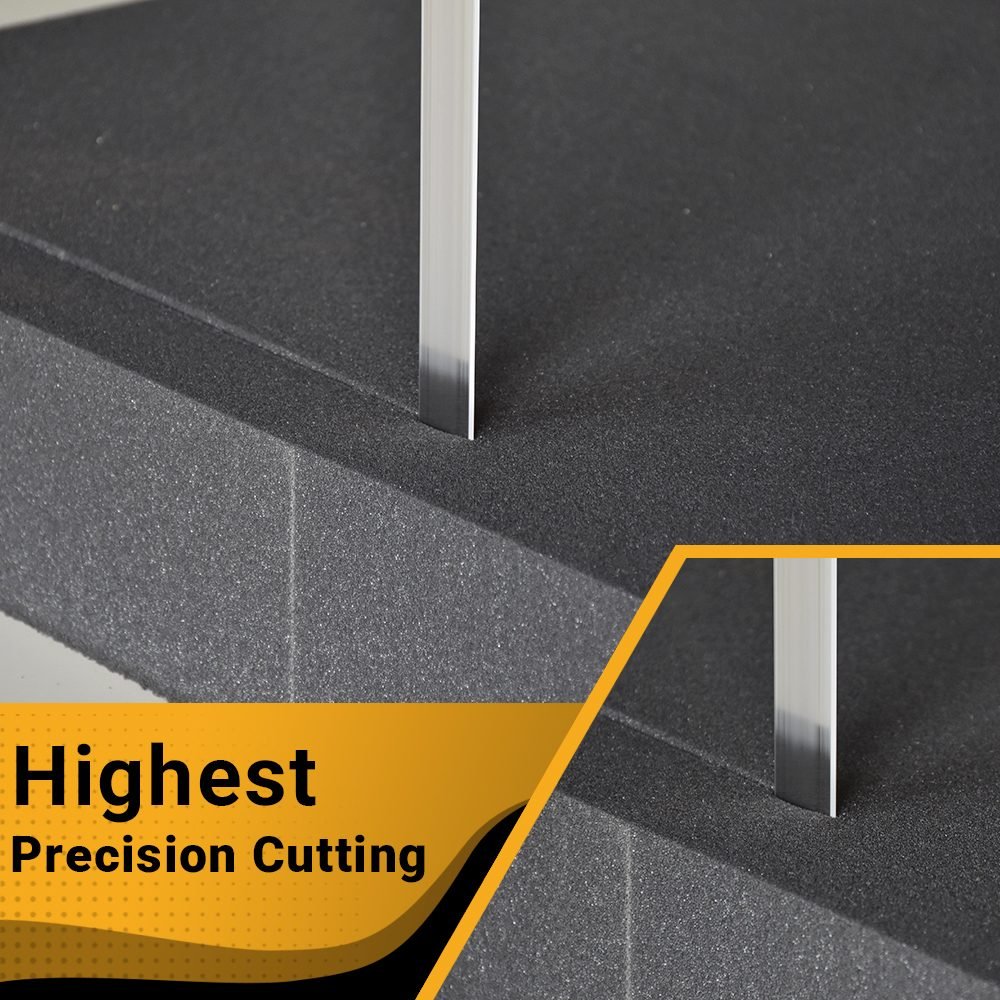

LQ Vertical Foam Cutting Machine slices and trims foam blocks while cutting sheets with rectangular configurations. Features advanced linear guide technology with grinding dust extraction and accurate orientation hand wheel for precision block trimming and sheet cutting operations.

Download PDF

Customer Service

Share your contact information – our engineers respond 24/7.

Vertical Foam Cutting Machine

Highest Precision Cutting

Accurate Orientation Wheel

Movable Worktable

Technical Specification

|

Inside Table Size |

W1720mm*L2440mm |

Outer Table Size |

W2000mm*L2440mm |

|

Cutting Height |

1200mm(1300mm/1400mm optiona) |

Blade Length |

L8900*W32*T0.45mm |

|

Cutting Thickness |

2mm |

Machine Size |

L4000*W4700*H2500mm |

What Our Customers Say

GENMAX Fuels Portugal’s Foam Cutting Efficiency

Mexican Foam Producers Choose GENMAX

Ready to see similar improvements in your facility? Click for a no-obligation consultation.

Most Popular Questions

Yes, the cutting head height is adjustable and can be positioned near the foam block for optimal cutting results, accommodating different material thicknesses and cutting requirements.

Yes, custom cutting heights are available: 1.3m/1.4m/1.5m/1.7m

Note: Pricing will need to be recalculated for these custom heights as they require modifications to the standard machine configuration.

The machine handles a comprehensive range:

Polyurethane Foams:

- Ether-based PU

- Flame-protected ether PU

- High resilience PU foam

Viscoelastic Materials:

- Viscoelastic ether-based PU

- Flame-protected viscoelastic ether PU

Specialized PU Foams:

- Combustion-modified highly resilient PU

- Reticulated ether-based PU

Ester-Based Materials:

- Ester-based polyurethane

- Reticulated ester-based PU foam

- CM-PU ester foam

Alternative Materials:

- Rebonded polyurethane

- PU gel foam

- Extruded polyethylene

- Low density polyethylene

Rubber and Other Materials:

- EVA, sponge rubber, natural rubber

- Mineral wool, viscose foam

No density limit - the machine can cut hundreds of different densities. This vertical cutting machine is versatile enough to handle:

Various sponge densities (from very soft to firm)

Very hard materials like EVA

Honeycomb foam

All the previously mentioned foam types (PU, viscoelastic, etc.)

Available options:

- 1200mm cutting height → 8900 × 25 × 0.45mm blade

- 1300mm cutting height → 9100 × 25 × 0.45mm blade

- 1500mm cutting height → 9500 × 25 × 0.45mm blade

We provide a standard warranty period of 12 months from the date of installation, covering any manufacturing defects and ensuring customer satisfaction.

The lead time typically ranges from 30 to 90 days, depending on the model and order specifications. We will provide an estimated delivery date upon order confirmation.

Yes, we offer extensive after-sales support, including technical assistance, maintenance services, and access to spare parts to ensure the longevity of your Tape Edge Machines.

Absolutely! We can provide references and testimonials from our satisfied customers to demonstrate the reliability and performance of our Tape Edge Machines.

Recommend

Foam Rebonding Machine Recycling Equipment (With Steam)

The RF Foam Rebonding Machine recycles foam waste from conversion plants. It rebonds chips into blocks. Crushed foam goes into the optional silo. Then, it moves to the weight box. The team sends set amounts to the mixing tank. After that, they enter two molds: rectangle or cylinder for hot press and steam. Manufacturers can make the rebonded blocks into many end products. This Foam Rebonding Machine has an electric control panel. It has a weight display and a metering system. This controls the dosage of chemicals and steam.

Download PDF Foam Shredding Machine Crusher

Download PDF

Profile Foam Cutting Machine

Download PDF